Confined spaces, common in numerous industries, present unique challenges to workers and supervisors alike, with one of the primary concerns being maintaining and monitoring oxygen levels. Oxygen, the life-sustaining gas we often take for granted, plays a pivotal role in these environments, supporting human life and affecting safety protocols, especially when its levels fluctuate.

As we delve deeper into the intricacies of confined spaces, we’ll explore the significance of oxygen, understand its effects on human health at varying concentrations, and emphasize the crucial need for continuous monitoring. This article will also discuss the myriad factors influencing oxygen levels, the dangers of oxygen enrichment and depletion, and offer guidance on best practices, emergency response, and the imperative of thorough training. Join us as we navigate the complexities of confined spaces and shed light on the importance of being oxygen-aware.

Importance of Maintaining Proper Oxygen Levels In Confined Space

Confined spaces are areas not primarily designed for human occupancy and have restricted means of entry and exit. These spaces include storage tanks, silos, pits, tunnels, and pipelines.

Confined spaces are prevalent in various industries, including construction, manufacturing, agriculture, and utilities. These spaces are often necessary for storage, maintenance, repair, or inspection operations. However, their unique characteristics make them potential sites for safety hazards, necessitating strict protocols for entry and work within these areas. Maintaining proper oxygen levels in confined space is for many reasons:

Human Safety

- Vital for Respiration: The primary reason for oxygen’s importance is its role in respiration. Our body needs a consistent and adequate oxygen supply to function correctly.

- Preventing Cognitive Impairment: At decreased oxygen levels (below 19.5%), cognitive abilities can get impaired, leading to poor decision-making. This could escalate the risks if an emergency arises.

- Preventing Hypoxia: Prolonged exposure to reduced oxygen levels can lead to hypoxia, insufficient oxygen reaching the body’s tissues. This can have long-term health effects and can be fatal in extreme cases.

Combustion Hazards

- Accelerated Combustion: High oxygen environments can make combustible materials ignite more easily and burn faster and hotter than normal.

- Risk of Flash Fires: In environments with elevated oxygen levels, there’s an increased risk of flash fires, which are sudden, intense fires caused by ignition in a mixture of air and flammable substances.

Indicator of Other Gases

- Sign of Displacement: When oxygen levels decrease, it can be a sign that another gas is displacing it. Recognizing this can be the first step in identifying a potentially hazardous gas leak.

- Detection of Toxic Gases: Gases like carbon monoxide and hydrogen sulfide can displace oxygen. Monitoring oxygen levels can thus indirectly alert workers to these lethal gases.

Equipment Efficiency and Lifespan

- Corrosion Prevention: In spaces where machinery or metal equipment is stored, high oxygen levels can accelerate the oxidation rate, increasing corrosion.

- Ensuring Combustion Engines Work: Maintaining oxygen levels is critical for efficient operation if a confined space houses a combustion engine or furnace.

Legal and Regulatory Compliance

- Avoiding Penalties: Many jurisdictions have established regulations on safe working conditions, including oxygen levels in confined spaces. Keeping within these levels ensures businesses avoid potential legal penalties.

- Upholding Occupational Standards: By ensuring proper oxygen levels, businesses demonstrate a commitment to the well-being of their employees and adherence to occupational safety standards.

Enhanced Productivity

- Fewer Interruptions: Workers can continue their tasks without frequent disruptions with consistent monitoring and maintaining optimal oxygen levels.

- Reduction in Health-Related Absences: Maintaining a safe environment reduces health complications for employees, leading to fewer absences and improved productivity.

Industries can ensure immediate and long-term safety, efficient operations, and a healthy workforce by comprehending the multifaceted importance of oxygen in confined spaces.

Oxygen and Its Role in Confined Spaces

Oxygen plays a critical role in sustaining life, as it’s essential for the respiration of most organisms, including humans. Oxygen availability becomes even more crucial in confined spaces due to limited ventilation and the potential for oxygen depletion or enrichment, which can lead to hazardous conditions. Here’s an overview of oxygen’s role in confined spaces and the associated risks:

Role of Oxygen in Supporting Human Life

Oxygen is essential for supporting human life as it is critical in various biological processes within the body. Without an adequate supply of oxygen, human cells and tissues cannot function properly, leading to serious health issues or even death. Here are the key roles of oxygen in supporting human life:

- Cellular Respiration: Oxygen is fundamental for cellular respiration, a process in which our cells produce energy. During this process, oxygen reacts with glucose to produce carbon dioxide, water, and energy. This energy is vital for every physiological function, from muscle contraction to synthesizing enzymes and neurotransmission.

- Brain Function: Despite only 2% of our body weight, the brain consumes around 20% oxygen. Oxygen is critical for cognitive functions, including memory, attention, and decision-making. A shortage can impair these functions, leading to confusion, dizziness, and impaired judgment.

- Detoxification: Oxygen also plays a role in the body’s detoxification processes. It helps convert toxins into water and carbon dioxide, allowing our bodies to eliminate them easily.

- Immune System Support: Oxygen aids in producing reactive oxygen species and other reactive compounds used by the immune system to kill pathogens and infected cells.

Potential Hazards of Inadequate Oxygen Levels in Confined Spaces

Inadequate oxygen levels in confined spaces can give rise to numerous hazardous situations that endanger the health and safety of individuals. Understanding these potential hazards is crucial to prevent accidents and ensure the well-being of anyone working in or entering such spaces. Here are the main hazards associated with inadequate oxygen levels:

- Hypoxia: Oxygen levels lower than the typical 20.9% concentration can lead to hypoxia, where insufficient oxygen reaches the tissues. Symptoms can range from shortness of breath and rapid heartbeat to severe cases like cognitive impairment, organ dysfunction, or death.

- Impaired Cognitive and Physical Performance: Reduced oxygen levels can affect an individual’s ability to think clearly, impair judgment, and decrease motor skills, particularly crucial in confined space environments where precise actions and decisions might be required.

- Accelerated Fatigue: Low oxygen concentrations can lead to faster exhaustion. Workers might tire more quickly, decreasing productivity and increasing susceptibility to other hazards.

- Respiratory Distress: A sharp decrease in oxygen levels can lead to difficulty breathing, chest pain, and eventual respiratory failure if not addressed promptly.

- Loss of Consciousness: Extremely low oxygen levels can cause individuals to lose consciousness. This is particularly dangerous in confined spaces where swift evacuation or medical intervention might be challenging.

- Long-term Health Effects: Chronic exposure to slightly reduced oxygen levels, even if not immediately life-threatening, can have long-term health impacts, including cardiovascular diseases or neurological issues.

In summary, while oxygen is a silent, invisible factor, its role is paramount in sustaining life and ensuring the safety of workers in confined spaces. Recognizing its importance and understanding the implications of its scarcity can guide industries in safeguarding their employees while maintaining efficient operations.

Oxygen Concentrations and Health Effects

Oxygen concentration in our air is about 20.9% under standard atmospheric conditions. However, variations in this concentration, especially in confined spaces, can result in significant health effects.

Oxygen Concentration Levels and Effects on the Human Body

Oxygen concentration levels in the air directly impact the human body’s ability to function properly. The effects of different oxygen concentrations can vary from mild discomfort to life-threatening situations. Here are the effects of varying oxygen concentration levels on the human body:

- Above 23.5% (Hyperoxic Environment): Increased risk of fire and explosion, especially if flammable materials are present. On the physiological side, high oxygen levels can lead to oxygen toxicity, affecting the central nervous system and the lungs.

- 21% (Normal Atmospheric Concentration): Safe and normal human breathing conditions. This is the standard oxygen concentration we encounter daily.

- 19.5% – 21%: Still generally safe for breathing, but it’s the threshold where OSHA (Occupational Safety and Health Administration) considers an environment to be oxygen-deficient.

- 15% – 19%: Decreased ability to work strenuously and impaired coordination. Rapid breathing and increased heartbeat can be noticeable. Impaired thinking and attention may also occur.

- 12% – 15%: Breathing increases in rate and depth. Poor judgment and blue discoloration of the lips can be observed.

- 10% – 12%: Breathing becomes extremely labored. Nausea and vomiting may occur. Loss of consciousness can happen.

- 8% – 10%: Fainting, unconsciousness, bluish discoloration of the face and lips, nausea, and vomiting. Convulsions may occur. Resuscitation is possible if oxygen is administered immediately.

- Below 8%: Certain deaths within minutes due to respiratory failure.

Symptoms of Hypoxia (Oxygen Deficiency)

Hypoxia in confined spaces can arise for several reasons, including oxygen displacement by other gases, chemical reactions, or biological processes consuming oxygen.

- Mild Hypoxia: Shortness of breath, rapid breathing, increased heart rate, light-headedness, sweating, and reduced peripheral vision.

- Moderate Hypoxia: Cyanosis (bluish or purplish discoloration of the skin), confusion, impaired judgment and coordination, coughing, and decreased response to stimuli.

- Severe Hypoxia: Difficulty breathing, seizures, fainting, coma, and eventually, death.

Symptoms of Hyperoxia (Excess Oxygen)

Excessing oxygen might be rare in confined spaces, but it’s not impossible, especially if used or stored in the area.

- Mild Hyperoxia: No apparent immediate symptoms in the short term.

- Moderate to Severe Hyperoxia (after prolonged exposure): Oxygen toxicity, which can lead to lung issues such as inflammation, scarring, or pulmonary edema. In extreme cases, central nervous system effects can include symptoms like nausea, twitching, dizziness, vision changes, seizures, or respiratory failure.

Understanding these concentration levels and their effects can be lifesaving, especially when planning and conducting operations in confined spaces. Regular monitoring, safety precautions, and training can go a long way in preventing hypoxic or hyperoxic incidents.

Monitoring Confined Space Oxygen Levels

Monitoring oxygen levels in confined spaces is paramount to ensure the safety of workers and prevent potential hazards. Given the risks associated with oxygen-deficient or oxygen-enriched environments, having reliable methods and tools is vital.

Methods and Tools for Monitoring Oxygen Levels

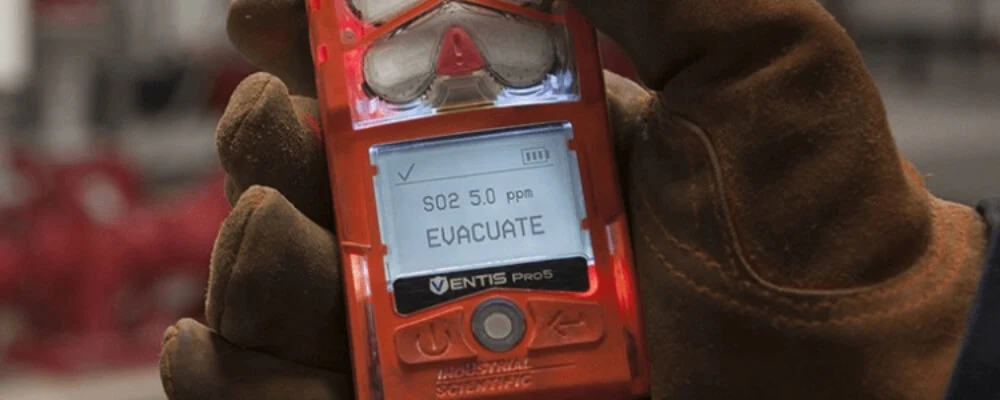

1. Portable Gas Detectors

Functionality: These handheld devices are designed to measure the concentration of oxygen and often other gases in the air. They provide instant readings and are crucial for workers entering a confined space.

Advantages:

- Mobility: Their compact size and portability make them ideal for spot checks and entry testing.

- Multiple Gas Detection: Many modern gas detectors can detect multiple gases simultaneously, offering a comprehensive safety check.

- Alarms typically come with visual, audible, or vibratory alarms that activate when oxygen levels are outside the safe range or when hazardous gases are detected.

- Data Logging: Some advanced models can store data for later analysis, which aids in safety audits and investigations.

2. Continuous Monitoring Systems

Functionality: These systems are designed to provide ongoing, real-time monitoring of oxygen and other gas concentrations in a confined space. They often involve a fixed or semi-fixed installation with sensors placed strategically within the space.

Advantages:

- Real-time Data: They offer continuous feedback, ensuring that any changes in oxygen levels are immediately detected.

- Integration with Other Systems: These monitoring systems can often be integrated with ventilation systems to automatically increase or decrease ventilation based on the readings.

- Centralized Monitoring: Many systems can transmit data to a centralized location, allowing supervisors or safety personnel to oversee multiple confined spaces simultaneously.

- Long-Term Analysis: Continuous data logging provides insights into trends and potential issues, helping in preventative maintenance and hazard anticipation.

Benefits of Monitoring Oxygen Levels

- Ensuring Worker Safety: Real-time and accurate monitoring of oxygen levels ensures that workers are not exposed to hypoxic or hyperoxic conditions that could jeopardize their health or lives.

- Early Detection of Hazards: Monitoring tools can detect not only oxygen imbalances but also the presence of other hazardous gases, ensuring timely interventions.

- Compliance with Safety Regulations: Regulatory bodies like OSHA have set guidelines for oxygen levels in confined spaces. Monitoring ensures compliance, thus avoiding potential legal repercussions and fines.

- Increased Operational Efficiency: With continuous monitoring, work can proceed confidently, reducing interruptions and shutdowns related to safety concerns.

In summary, effectively monitoring oxygen levels in confined spaces using portable gas detectors and continuous monitoring systems is a cornerstone of confined space safety. These tools can prevent accidents and save lives when used correctly and regularly.

Factors Affecting Confined Space Oxygen Levels

Confined spaces have specific challenges, especially when maintaining safe oxygen levels. Multiple factors can influence these levels, and understanding them is crucial to ensure a safe environment for workers.

Factors Influencing Oxygen Levels in Confined Spaces

Several factors can influence the oxygen levels in confined spaces, potentially leading to hazardous conditions. Understanding these factors is crucial to ensure the safety of individuals working or entering such spaces. Here are the main factors that can affect oxygen levels in confined spaces:

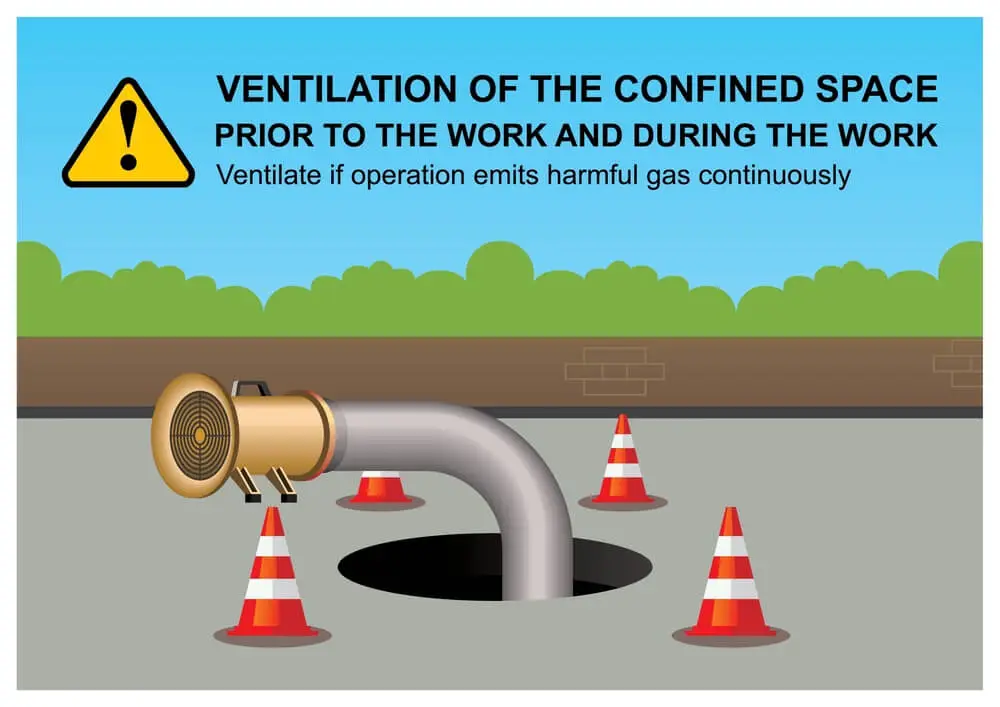

1. Ventilation

- Poor Ventilation: Confined spaces with limited or ineffective ventilation can quickly deplete oxygen as workers consume the available oxygen and exhale carbon dioxide.

- Effective Ventilation: Proper ventilation can introduce fresh air, ensuring a consistent oxygen supply and diluting or removing hazardous gases.

2. Combustion Processes

- Equipment, such as engines or burners operating within or near the confined space, consumes oxygen during combustion. This can rapidly reduce available oxygen levels.

3. Biological Activities

- The decomposition of organic materials or the presence of microorganisms (like bacteria) can consume oxygen and produce other gases, potentially reducing the oxygen content.

4. Rusting or Oxidation

- Oxidation of materials, like rusting iron, can consume oxygen and reduce its concentration in the confined space.

5. Displacement by Other Gases

- In some confined spaces, other gases like carbon dioxide, methane, or nitrogen might seep in or be released, displacing the available oxygen.

6. Work Processes and Equipment

- Certain industrial processes or equipment can either consume oxygen or release other gases. For example, welding in a confined space consumes oxygen and produces gases that can displace oxygen or pose additional hazards.

7. Temperature and Humidity

- Elevated temperatures can increase the rate of chemical reactions or biological activities that affect oxygen levels. High humidity levels can exacerbate rusting or support bacterial growth, influencing oxygen concentrations.

8. Barometric Pressure Changes

- Changes in atmospheric pressure, such as during a storm, can affect the pressure inside the confined space, influencing gas concentrations.

Importance of Understanding These Factors

Understanding the factors that influence oxygen levels in confined spaces is crucial for several reasons:

- Anticipating Risks: Recognizing the factors influencing oxygen levels enables workers and supervisors to anticipate risks and take preventive measures before entering a confined space.

- Effective Monitoring: Knowing potential threats to oxygen balance helps choose the right monitoring equipment and establish safe entry and work procedures.

- Optimal Work Planning: Understanding these factors allows for better planning of work activities, ensuring tasks that might deplete oxygen are scheduled when adequate safety measures are in place.

- Enhanced Training: Workers can be better trained to recognize and mitigate specific risks if they know the factors influencing oxygen levels.

In conclusion, while confined spaces come with their unique set of challenges, a thorough understanding of the factors affecting oxygen levels ensures that safety measures are tailored to the specific risks of each space. This proactive approach maximizes worker safety and operational efficiency.

Safety Measures and Best Practices

The risk of oxygen-related incidents in confined spaces can be effectively reduced by following comprehensive safety measures. These measures can be grouped according to the hierarchy of controls, a systematic approach that prioritizes intervention strategies based on their effectiveness.

Hierarchy of Controls

1. Engineering Controls

These are physical changes to the workplace or work processes to prevent exposure to hazards.

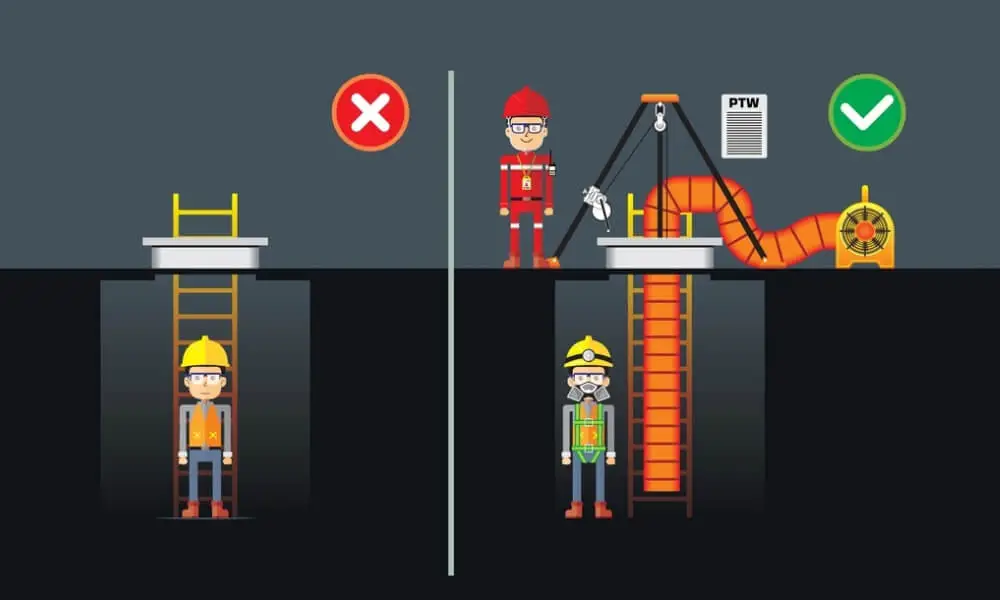

- Proper Ventilation: Install ventilation systems to introduce fresh air into the confined space. This helps maintain an adequate oxygen supply and remove or dilute harmful gases.

- Isolation: Separate the confined space from processes that might introduce oxygen-depleting substances. This could include using barriers, distance, or sealing off certain areas.

- Continuous Monitoring Systems: Deploy fixed oxygen monitors that can provide real-time data on oxygen levels, triggering alarms if levels fall outside safe limits.

- Safety Signage: Clearly mark confined space entry points with warning signs about potential oxygen hazards.

2. Administrative Controls

These are work policies, procedures, or schedule changes to reduce or eliminate hazards.

- Training and Education: Conduct regular training sessions for employees on the risks associated with confined spaces and the importance of oxygen level monitoring.

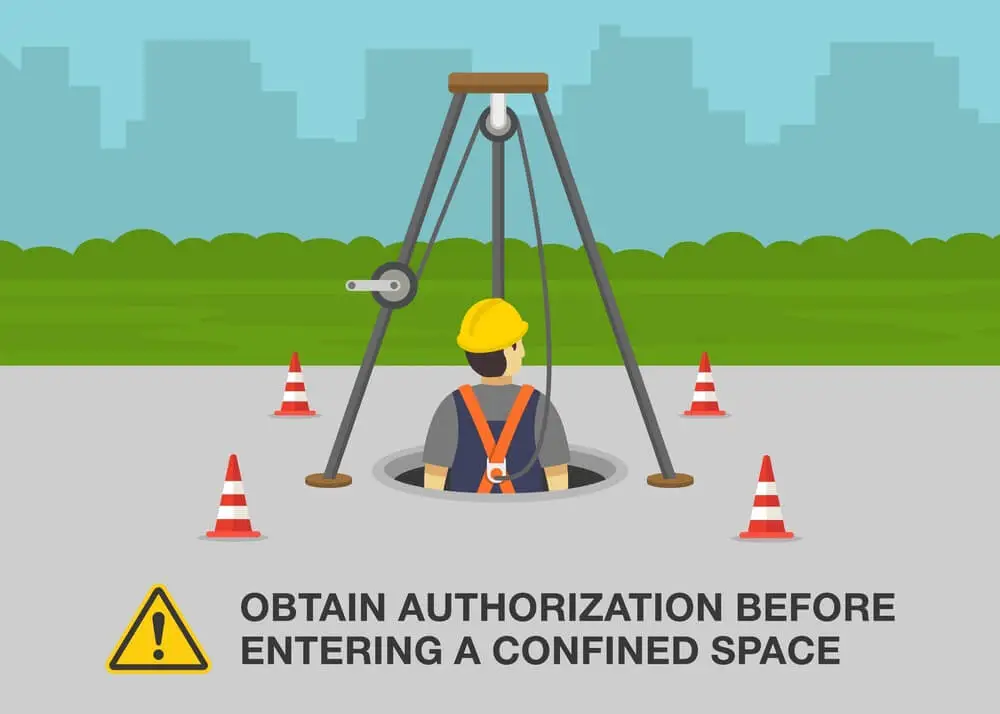

- Permit-to-Work System: Implement a permit system for confined space entry, ensuring proper checks are conducted before anyone enters the space.

- Regular Inspections: Schedule routine checks of confined spaces to detect any issues that could compromise oxygen levels.

- Safe Work Procedures: Establish specific protocols for activities like welding or the use of machinery inside confined spaces.

- Emergency Response Plans: Prepare and practice clear response strategies for potential oxygen-related emergencies.

3. Personal Protective Equipment (PPE)

These are wearable items that protect workers from specific hazards.

- Respiratory Protection: Equip workers with appropriate respirators or self-contained breathing apparatus (SCBA) when there’s a risk of oxygen deficiency or enrichment.

- Gas Detection Devices: Provide workers with portable gas detectors to continuously measure oxygen levels inside the confined space.

- Communication Devices: Supply workers with two-way radios or other communication tools to maintain contact with those outside the confined space.

- Protective Clothing: In spaces with potential chemical hazards, ensure workers wear protective clothing to guard against skin contact.

Confined spaces present unique challenges regarding oxygen levels, but these risks can be significantly mitigated with correctly applying the hierarchy of controls. By combining engineering solutions, administrative policies, and personal protection, industries can create a multi-layered defense against oxygen-related incidents, ensuring the safety and health of their workers.

Emergency Response

Responding swiftly and effectively to oxygen-related emergencies in confined spaces is crucial to safeguarding workers’ lives. A systematic approach ensures a coherent response and reduces the potential for further harm.

Procedures for Oxygen-Related Emergencies

1. Immediate Notification

Workers should be trained to immediately notify supervisors and coworkers if they suspect oxygen levels are outside the safe range or if they experience symptoms of oxygen imbalance.

2. Evacuation

- Pre-Designated Exit Routes: All workers should be familiar with multiple exit routes from the confined space.

- Immediate Exit: Upon suspecting an oxygen-related issue, workers should leave the confined space immediately.

- Avoid Panic: Panic can exacerbate the situation, so training should emphasize the importance of orderly evacuations.

3. Rescue

- No Unauthorized Rescues: Untrained personnel should not attempt rescues, as they may become victims themselves.

- Use of PPE: Rescuers should wear appropriate PPE, including respiratory protection, to protect against potential hazards.

- Rescue Equipment: Hoists, harnesses, and other specialized rescue equipment should be readily available near confined space entry points.

4. First Aid

- Oxygen Administration: Provide oxygen to affected individuals, especially if they show symptoms of hypoxia.

- CPR: If the victim is unconscious and not breathing, begin cardiopulmonary resuscitation (CPR) immediately.

Immediate Medical Attention: Even if victims appear to recover, they should be evaluated by medical professionals as oxygen deprivation can have delayed effects.

Conclusion

Navigating the intricacies of confined spaces is no small task, underscoring the significance of understanding and managing oxygen levels within such environments. From its foundational role in supporting life to the dangers posed by its absence or excess, the equilibrium of oxygen in confined spaces is paramount to ensuring safety. By continuously monitoring these levels, recognizing the myriad factors that can influence them, and adhering to best practices and safety protocols, potential hazards can be mitigated.

Moreover, comprehensive training and awareness cannot be overstated, as they equip workers and supervisors with the knowledge and skills to respond effectively in emergencies. As we conclude our exploration of this topic, let us remember that awareness, vigilance, and education form the cornerstone of safety in confined spaces.