Electricity powers our workplaces and is vital for daily operations, but it also poses significant risks if not managed correctly. “Electrical Safety Toolbox Talk: Ensuring a Safe Workplace” delves into the critical importance of electrical safety, providing practical insights and guidelines for recognizing hazards, adhering to safety protocols, and promoting a culture of awareness.

This blog serves as a comprehensive resource to help you conduct effective safety talks, ultimately aiming to protect everyone in the workplace from electrical accidents and ensure a secure, efficient working environment.

Why Electrical Safety Matters

Electricity is an invisible hazard that can cause severe injuries or even fatalities if not handled properly. According to the Occupational Safety and Health Administration (OSHA), electrical hazards are one of the leading causes of workplace injuries. Implementing regular electrical safety toolbox talks can help prevent accidents by educating employees about potential risks and safety protocols.

Common Electrical Hazards

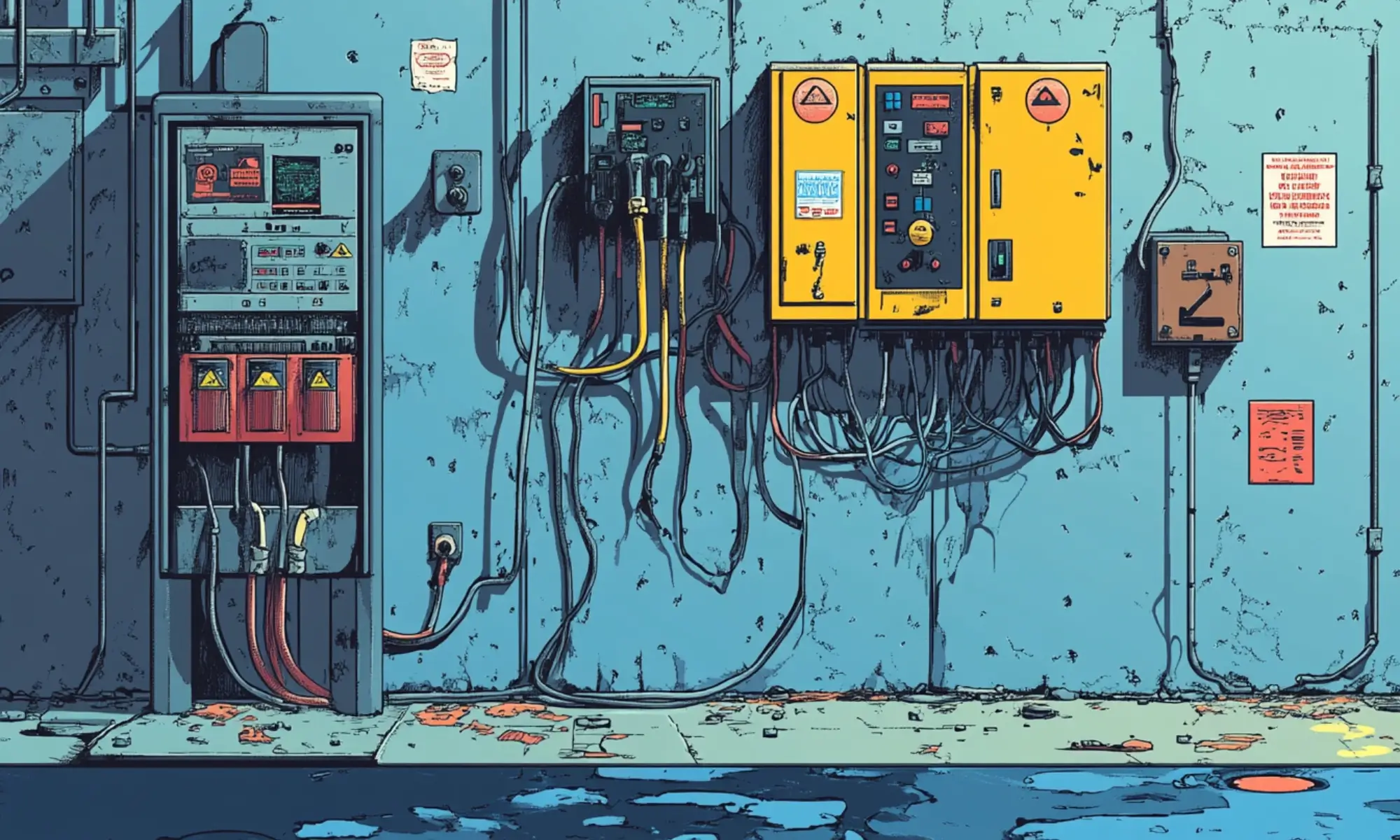

Understanding the common electrical hazards is the first step in preventing accidents. Some of the most prevalent risks include:

- Contact with Energized Equipment: Touching live electrical parts can lead to shocks or electrocution.

- Arc Flashes and Arc Blasts: Sudden releases of electrical energy can cause burns and other serious injuries.

- Damaged Insulation: Exposed wires increase the risk of shocks and short circuits.

- Overloaded Circuits: Excessive electrical load can cause overheating and fires.

- Improper Grounding: Electrical systems may become unstable without proper grounding, leading to shocks.

Key Components of an Electrical Safety Toolbox Talk

An effective toolbox talk should be concise, engaging, and informative. Here are the key components to include:

1. Introduction and Objective

An effective electrical safety toolbox talk should start by capturing the attendees’ attention and setting clear expectations. Introduce the topic by emphasizing the critical importance of electrical safety in the workplace. Outline the session’s objectives, such as increasing awareness of electrical hazards, understanding safety protocols, and fostering a culture of safety mindfulness among all employees.

Key Points:

- State the purpose of discussing electrical safety.

- Highlight the significance of preventing electrical accidents.

- Outline the specific goals of the toolbox talk.

- Encourage active participation and attentiveness.

- Set a positive tone for safety commitment.

2. Recent Incidents and Lessons Learned

Discussing recent electrical incidents, whether within the company or from industry examples, helps illustrate the real dangers associated with electricity. Analyze what went wrong in these incidents and extract valuable lessons. This approach personalizes the risks and reinforces the need for strict adherence to safety protocols to prevent similar occurrences.

Key Points:

- Share details of recent electrical accidents or near-misses.

- Identify the causes and contributing factors.

- Discuss the impact on individuals and operations.

- Highlight preventive measures that could have averted the incidents.

- Encourage employees to learn from these examples.

3. Understanding Electrical Hazards

Educate employees about the various types of electrical hazards they may encounter. Explain how electric shocks, burns, arc flashes, and arc blasts occur and the potential injuries they can cause. By understanding these hazards, employees can better recognize dangerous situations and proactively protect themselves and others.

Key Points:

- Define common electrical hazards (shocks, burns, arc flashes/blasts).

- Explain the mechanisms of how these hazards occur.

- Describe the potential health effects and injuries.

- Identify workplace scenarios where these hazards may be present.

- Stress the importance of hazard recognition and avoidance.

4. OSHA Regulations and Compliance

Reviewing OSHA regulations ensures that employees are aware of legal requirements related to electrical safety. Discuss relevant standards, such as 29 CFR 1910.331 – 1910.335, and explain how compliance avoids penalties and protects everyone’s well-being. Emphasize that following these regulations is a shared responsibility.

Key Points:

- Introduce key OSHA electrical safety standards.

- Explain employer and employee obligations under the law.

- Highlight the consequences of non-compliance (fines, injuries).

- Stress the role of regulations in preventing accidents.

- Encourage adherence to standards as part of daily routines.

5. Inspection of Electrical Equipment

Regular inspection of electrical equipment is vital to identify and rectify potential hazards before they cause harm. Teach employees how to properly inspect tools, cords, and devices for signs of wear, damage, or malfunction. Establish clear procedures for reporting defective equipment and promptly removing it from service.

Key Points:

- Emphasize inspecting equipment before each use.

- Identify signs of damage (frayed cords, cracked casings).

- Explain how to report and tag defective items.

- Stress not using equipment that appears unsafe.

- Encourage a proactive approach to equipment safety.

6. Safe Work Practices

Outline the best practices employees should follow when working with or around electricity. This includes de-energizing equipment before maintenance, using tools correctly, and maintaining a tidy work environment to prevent accidents. Reinforce that safe work practices are essential in reducing risks associated with electrical hazards.

Key Points:

- Advise always to de-energize and lock out equipment before work.

- Promote proper use and handling of electrical tools.

- Encourage keeping work areas dry and organized.

- Highlight the importance of following established procedures.

- Remind employees to stay alert and focused on safety.

7. Personal Protective Equipment (PPE)

Using appropriate PPE is a critical line of defence against electrical injuries. Discuss the types of PPE required for different tasks, such as insulated gloves, safety glasses, and flame-resistant clothing. Provide guidance on PPE’s correct use, care, and limitations to ensure it offers maximum protection.

Key Points:

- List necessary PPE for electrical tasks.

- Demonstrate how to properly wear and adjust PPE.

- Explain how PPE protects against specific hazards.

- Instruct on inspecting and maintaining PPE.

- Emphasize never compromising on PPE usage.

8. Proper Grounding and Circuit Protection

Explain the importance of proper grounding in preventing electrical shocks and equipment damage. Discuss how Ground Fault Circuit Interrupters (GFCIs) and circuit breakers function to protect against electrical faults. Educate employees on checking for proper grounding and using circuit protection devices correctly.

Key Points:

- Define the purpose of grounding electrical systems.

- Describe how GFCIs and circuit breakers enhance safety.

- Show how to verify equipment is properly grounded.

- Warn of risks associated with improper grounding.

- Encourage routine testing of protective devices.

9. Working Near Power Lines

Special precautions are necessary when working near overhead or underground power lines. Define the minimum safe distances and explain the potential dangers of violating these boundaries. Provide guidelines on using insulated equipment, spotters, and safe operating procedures to prevent accidental contact.

Key Points:

- State safe clearance distances from power lines.

- Alert to the dangers of overhead and buried lines.

- Instruct on safe equipment use near power lines.

- Recommend using spotters when necessary.

- Stress the importance of obtaining utility locates before digging.

10. Emergency Response Procedures

Prepare employees to respond effectively in the event of an electrical emergency. Outline the steps to take if someone is shocked or electrocuted, including ensuring personal safety before assisting others. Provide information on handling electrical fires and the importance of prompt communication with emergency services.

Key Points:

- Explain immediate actions for electrical accidents.

- Stress does not touch victims until the power is off.

- Outline procedures for using fire extinguishers on electrical fires.

- Provide emergency contact numbers and reporting protocols.

- Encourage calm, swift, and safe responses.

11. Avoiding Overloads and Proper Circuit Use

Teach employees how to prevent overloading circuits, which can lead to fires and equipment damage. Discuss the dangers of using inappropriate extension cords and daisy-chaining power strips. Emphasize the importance of adhering to electrical load capacities and reporting any circuit breaker or outlet issues.

Key Points:

- Explain what causes circuit overloads.

- Advise against plugging multiple devices into one outlet.

- Instruct on selecting proper extension cords for the load.

- Warn of the hazards of bypassing safety devices.

- Encourage reporting frequent trips or electrical issues.

12. Employee Engagement and Feedback

Foster a culture where employees feel comfortable sharing their insights and concerns about electrical safety. Encourage questions during the toolbox talk and invite feedback on safety practices. Highlight that continuous improvement depends on everyone’s active participation and commitment to safety.

Key Points:

- Invite open discussion and questions.

- Encourage the sharing of experiences and suggestions.

- Acknowledge contributions to safety improvements.

- Reinforce that safety is a shared responsibility.

- Commit to addressing concerns and updating practices as needed.

By thoroughly addressing each of these components, your electrical safety toolbox talk will be comprehensive and engaging, equipping employees with the knowledge and motivation to maintain a safe working environment.

General Electrical Safety Tips

Implementing basic electrical safety measures is crucial for preventing workplace accidents and injuries. Let’s discuss essential tips that everyone should follow to maintain a safe environment when working with or around electricity.

Use Ground Fault Circuit Interrupters (GFCIs)

Ground Fault Circuit Interrupters, commonly known as GFCIs, are devices designed to protect people from electric shocks caused by faults in electrical devices or wiring. They work by monitoring the electrical current flowing in a circuit and quickly shutting off the power if they detect an imbalance between the outgoing and incoming current, which could indicate a current leakage to the ground (a ground fault). This rapid response can prevent serious injuries or fatalities by stopping the flow of electricity through a person’s body.

Key Points:

- Protection Against Shock: GFCIs reduce the risk of electric shock in wet or damp environments, such as bathrooms, kitchens, and outdoor areas.

- Easy Installation: They can be installed in place of standard electrical outlets or incorporated into circuit breakers.

- Testing: Regularly test GFCIs using the “Test” and “Reset” buttons to ensure they function properly.

- Compliance: Electrical codes in specific areas often require the use of GFCIs to enhance safety.

Avoid Overloading Outlets

Overloading an electrical outlet occurs when too many devices are plugged into a single outlet or circuit, exceeding its designed capacity. This can cause the wiring to overheat, leading to melted insulation, sparks, or even electrical fires. Overloaded circuits may also trip breakers or blow fuses, interrupting power and potentially damaging equipment.

Key Points:

- Limit Devices: Plug only one high-wattage appliance into each outlet or circuit.

- Use Power Strips Wisely: If using power strips or extension cords, ensure they have built-in overload protection.

- Understand Circuit Capacity: Be aware of the amperage limits of your circuits and devices.

- Avoid Daisy-Chaining: Do not connect multiple extension cords or power strips together.

Proper Cord Management

Proper cord management involves organizing and securing electrical cords to prevent physical damage and minimize hazards. Loose or improperly placed cords can create tripping hazards, leading to falls and injuries. Additionally, kinked, pinched, or frayed cords can expose wires, increasing the risk of electric shock or fire.

Key Points:

- Secure Placement: Keep cords out of walkways or secure them with cord covers to prevent trips and falls.

- Avoid Damage: Do not run cords under carpets, through doorways, or across sharp edges.

- Regular Inspection: Check cords for signs of wear, such as cracks, frays, or exposed wires, and replace damaged cords immediately.

- Use Appropriate Lengths: Choose cords that are the correct length to avoid unnecessary slack or tension.

Stay Informed

Staying informed means keeping up-to-date with the latest electrical safety practices, standards, and regulations. Electrical safety is an evolving field, with new technologies and guidelines introduced to enhance protection against hazards. Regular training and education help ensure that individuals know current best practices and how to respond appropriately to electrical risks.

Key Points:

- Regular Training: Participate in electrical safety training sessions and refresher courses.

- Update on Standards: Stay informed about updates to electrical codes, such as those from OSHA or the National Fire Protection Association (NFPA).

- Share Knowledge: Encourage open communication about safety concerns and share new information with colleagues.

- Safety Culture: Promote a workplace culture that prioritizes safety and continuous learning.

By understanding and applying these general electrical safety tips, individuals and organizations can significantly reduce the risk of electrical accidents, ensuring a safer environment for everyone involved.

Conclusion

Electrical safety is a vital component of a safe and efficient workplace. By conducting regular electrical safety toolbox talks, you reinforce the importance of recognizing hazards, adhering to safety protocols, and using proper protective equipment. Remember that preventing electrical accidents is a collective responsibility that requires constant vigilance, education, and communication.

By implementing the key components outlined—ranging from understanding electrical hazards and complying with OSHA regulations to practising safe work habits and encouraging employee engagement—you create an environment where safety is ingrained in the company culture. Staying informed about the latest safety standards and fostering open discussions about electrical safety will protect your employees and enhance overall productivity and morale.

Commit to making electrical safety a priority every day. Encourage your team to apply these practices consistently, report any concerns promptly, and support one another in maintaining a safe workplace. Together, you can minimize risks and ensure that everyone goes home safely at the end of the day.