In the realm of food safety, maintaining appropriate temperatures is pivotal to preventing foodborne illnesses. The Hazard Analysis Critical Control Point (HACCP) system offers a structured approach to managing food safety by analyzing and controlling biological, chemical, and physical hazards throughout the food production and handling process. Central to HACCP is temperature control, which serves as a critical factor in ensuring that food remains safe for consumption.

This article delves into the intricacies of HACCP temperature requirements, highlighting safe and unsafe levels, and elucidates best practices for maintaining optimal food safety standards.

What is HACCP Temperature?

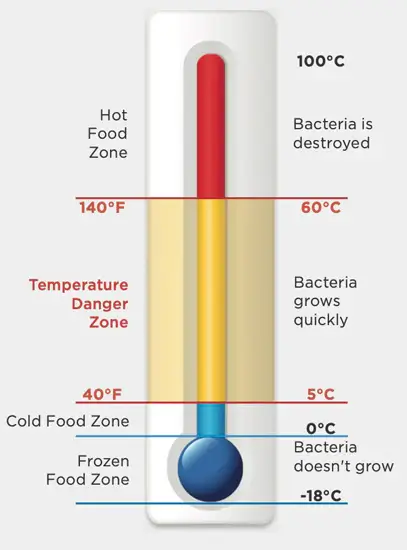

HACCP Temperature refers to the specific temperature guidelines and controls established within the Hazard Analysis Critical Control Point (HACCP) system to ensure food safety. These temperature parameters are designed to prevent the growth of harmful bacteria and other pathogens by keeping perishable foods outside the “danger zone” of 5°C to 60°C (41°F to 140°F). Specifically, HACCP Temperature management involves:

- Cold Control: Maintaining refrigerated foods at or below 5°C (41°F) and frozen foods at or below -18°C (0°F) to inhibit bacterial growth.

- Hot Control: Keeping hot foods at or above 60°C (140°F) to ensure that any potential pathogens are effectively controlled.

- Temperature Monitoring: Regularly measuring and recording temperatures during all stages of food handling, including delivery, storage, preparation, and service, to ensure compliance with safety standards.

By adhering to these temperature controls, the HACCP system proactively minimizes the risk of foodborne illnesses and ensures that food products remain safe for consumption throughout the supply chain.

The Importance of Temperature Control in HACCP

Temperature control is a cornerstone of the HACCP system, particularly in managing biological hazards such as bacterial growth. Bacteria thrive and multiply within a specific temperature range, commonly referred to as the “danger zone.” Understanding and controlling temperatures within and outside this range are essential to prevent foodborne illnesses.

The Danger Zone: 5°C to 60°C

The danger zone is the temperature range between 5°C and 60°C (41°F to 140°F) where bacteria can rapidly grow and reach harmful levels. Foods that remain within this zone for extended periods become breeding grounds for pathogens like Salmonella, E. coli, and Listeria, posing significant health risks to consumers.

Key Points:

- Biological Growth: Bacteria can double in number every 20 minutes within the danger zone.

- Food Types: High-risk foods such as meat, dairy products, and prepared dishes are particularly susceptible.

- Time Sensitivity: The longer food stays within this temperature range, the greater the risk of contamination.

Safe Temperature Levels: Keeping Food Outside the Danger Zone

To ensure food safety, it is imperative to maintain food temperatures outside the danger zone. This involves keeping cold foods below 5°C and hot foods above 60°C. Here’s a breakdown of safe temperature thresholds at various stages of food handling:

1. Deliveries

Objective: Ensure that incoming goods are received at safe temperatures to prevent introducing hazards into the kitchen or storage areas.

- Cold Foods: Must be delivered at 8°C or below (recommended by the Food Standards Agency to be 5°C or lower).

- Freezing Goods: Should arrive at -18°C or lower.

Best Practices:

- Use a between-pack temperature probe for efficient measurement.

- Record temperature upon receipt to decide on acceptance or rejection of deliveries.

2. Food Storage

Objective: Maintain stored foods at temperatures that inhibit bacterial growth.

- Chilled Foods: Keep at 5°C or below.

- Frozen Foods: Maintain at -18°C or lower.

- Chilled Display Equipment: Ensure foods are kept at 8°C or below when displayed.

Best Practices:

- Monitor fridge and freezer temperatures at least once daily.

- Use clean temperature probes to verify storage conditions.

- Limit the time chilled foods are kept at room temperature during preparation.

3. Food Preparation

Objective: Cook foods to temperatures that eliminate harmful bacteria.

- Cooking Temperatures:

- 80°C for at least 6 seconds

- 75°C for at least 30 seconds

- 70°C for at least 2 minutes

- 65°C for at least 10 minutes

- 60°C for at least 45 minutes

Best Practices:

- Use clean temperature probes to check core temperatures of cooked dishes.

- Ensure probes are sanitized between uses to prevent cross-contamination.

4. Food Service

Objective: Maintain hot foods at safe temperatures during holding and reheating processes.

- Hot Holding: Keep food at 63°C or above.

- Reheating: Reheat food thoroughly to 75°C; only reheat once.

Best Practices:

- Use suitable hot holding equipment to maintain required temperatures.

- Monitor and record temperatures regularly to ensure compliance.

- Discard foods that have been out of temperature control for extended periods (e.g., more than two hours).

5. Calibration and Validation

Objective: Ensure that temperature monitoring equipment provides accurate readings to maintain food safety.

Best Practices:

- Regularly calibrate thermometers using boiling water (100°C) and ice baths (0°C) to verify accuracy within ±1°C.

- Store probes properly to avoid damage and contamination.

- Replace batteries in digital probes promptly to ensure functionality.

Tools and Equipment for Temperature Monitoring

Accurate temperature measurement is essential for effective HACCP implementation. Various types of thermometers are available, each suited to specific monitoring needs:

- Between-Pack Probes: Ideal for measuring temperatures between packs or boxes of produce with rapid response times.

- Infrared Thermometers: Designed for surface temperature measurements.

- Penetration Probes: Required for core temperature measurements of foods.

- Digital Display Thermometers: Offer precise readings and are easy to use.

- Dial Thermometers: Provide reliable temperature measurements with analog displays.

- Thermapen Professional: A highly accurate food thermometer suitable for a wide temperature range (-49.9°C to 299.9°C).

Best Practices for Temperature Monitoring and Probe Care

Maintaining the integrity of temperature monitoring tools is crucial for reliable measurements:

- Cleanliness: Always clean temperature probes with anti-bacterial wipes after each use to prevent cross-contamination.

- Storage: Store probes in protective cases away from extreme temperatures and liquids.

- Handling: Avoid dropping or damaging probes to ensure their accuracy and longevity.

- Calibration: Regularly calibrate thermometers to maintain accuracy, checking against known temperature standards.

- Battery Maintenance: Replace batteries in digital probes promptly to avoid malfunctioning.

Conclusion

Temperature control is a fundamental aspect of the HACCP system, essential for safeguarding food from biological hazards. By understanding and adhering to safe and unsafe temperature levels, food businesses can significantly reduce the risk of foodborne illnesses. Implementing robust temperature monitoring practices, utilizing appropriate tools, and maintaining equipment accuracy are critical steps in ensuring the safety and quality of food products. Embracing these principles not only complies with regulatory standards but also fosters consumer trust and business reputation in the competitive food industry.