In the myriad terrains of industrial landscapes, where the line between safety and mishaps can be razor-thin, Personal Protective Equipment (PPE) emerges as the unsung sentinel. Among these, metatarsal guards, designed to be foot saviors, have been gaining ground. Whether navigating a construction site bustling with heavy machinery or managing the factory floor, these guards ensure that the metatarsal bones – those extending from your toes to the arch of your foot – remain unscathed.

In this comprehensive guide, we’ll walk you through the essence of metatarsal guards, exploring their safety benefits, delving into the diverse types available, and understanding the materials shaping them.

Beyond that, we’ll arm you with a checklist of features to prioritize when selecting one, shed light on the standards and certifications they should adhere to, and impart wisdom on their care and maintenance. Let’s embark on this enlightening journey, ensuring your every step is protected.

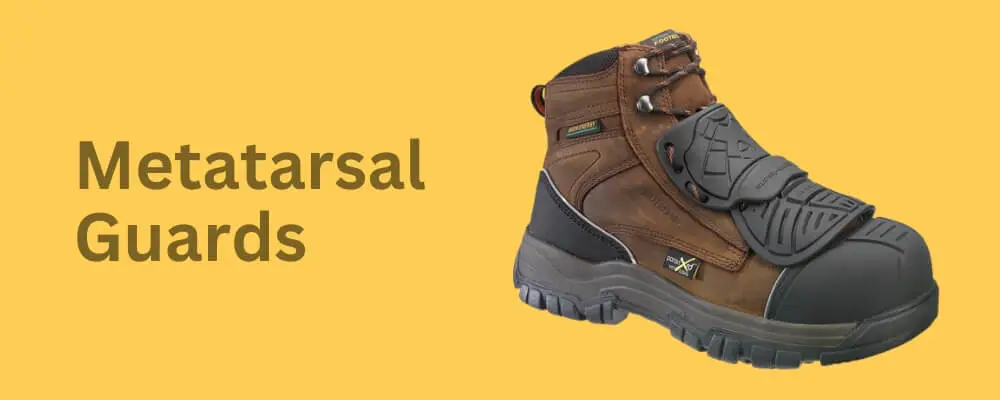

What are Metatarsal Guards?

Metatarsal guards are specialized protective equipment crafted to safeguard the metatarsal bones, which span from the toes to the arch of the foot. These bones are vulnerable to injuries, especially in work environments where heavy objects might drop or exert undue pressure on the foot. As a component of personal protective equipment (PPE), metatarsal guards act as a shield, deflecting and absorbing the force from such impacts, thus preventing potential fractures or other foot injuries.

People engaged in construction, manufacturing, and other heavy-duty sectors are often at a heightened risk of foot injuries. The likelihood of heavy materials or equipment falling is significant in these settings. To mitigate these risks, many safety regulations mandate using protective footwear, which often includes metatarsal guards. These guards, whether integrated into the shoe or attached externally, provide an essential layer of protection, ensuring the safety and well-being of workers in hazardous environments.

Safety Benefits Of Metatarsal Guards

Metatarsal guards offer a range of safety benefits, especially for those working in environments with potential foot hazards. Here are the safety benefits of using metatarsal guards:

- Prevention of Injuries: The primary benefit of metatarsal guards is the protection they offer against direct impacts. In industries where heavy objects or machinery parts can fall or roll, these guards act as a shield, protecting the delicate metatarsal bones from fractures and breaks.

- Reduction in Severity: Even if an accident occurs, the presence of a metatarsal guard can significantly reduce the severity of the injury. By dispersing the force of the impact over a larger area, the guard minimizes the direct force on any single point, thereby preventing or lessening potential damages.

- Protection from Compression: Beyond falling objects, workers might also encounter situations where their feet are squeezed or compressed, such as by machinery or heavy equipment. Metatarsal guards provide a rigid protective layer that helps to resist such compressive forces.

- Heat and Burn Protection: In some industrial settings, workers may be exposed to hot materials, sparks, or molten substances. Metatarsal guards, especially those made of specific materials, can offer protection against burns and heat-related injuries.

- Enhanced Worker Confidence: Knowing they are protected can boost workers’ confidence and allow them to focus better on their tasks. This mental assurance can, in itself, lead to safer practices and reduced risk-taking behavior.

- Cost-Efficiency: While this might not be a direct safety benefit, preventing injuries can lead to fewer missed workdays, lower medical expenses, and reduced compensation claims. In the long run, adopting metatarsal guards can lead to significant savings for companies, highlighting the economic benefit of safety.

- Compliance with Regulations: Many industries have strict safety regulations requiring protective equipment, including metatarsal guards. Using them ensures compliance, reducing the risk of legal repercussions and potential shutdowns.

In essence, metatarsal guards serve as a frontline defense against various foot-related hazards in the workplace. Their integration into safety gear ensures a holistic approach to worker protection, especially in high-risk environments.

Types of Metatarsal Guards

Metatarsal guards are pivotal in safeguarding the upper portion of the foot, primarily focusing on the fragile metatarsal bones. Their designs and applications can mainly be categorized into two distinct types: External Metatarsal Guards (Mets) and Internal Metatarsal Guards.

1. External Metatarsal Guards (Mets)

External Metatarsal Guards are independent protective apparatuses that attach externally to a worker’s footwear. These guards are typically designed to either strap on or clip onto a shoe, predominantly covering the instep and extending over the topmost part of the foot.

Advantages

The primary advantage of these guards lies in their versatility. Due to their detachable nature, they can be conveniently added to or removed from almost any shoe or boot. This characteristic renders them particularly beneficial for workers who may not always require metatarsal protection. Moreover, from a financial standpoint, they prove to be especially cost-effective.

For workers who possess safety shoes but sporadically find themselves in scenarios demanding added metatarsal protection, these external guards present a budget-friendly solution without compelling them to invest in entirely new specialized footwear.

Disadvantages

However, every silver lining has a cloud, and the external guards are no exception. From an aesthetic viewpoint, they might not appeal to all. Some workers may perceive them as less appealing or less comfortable than footwear with inbuilt protection.

Moreover, there’s a tangible risk associated with these external guards. If they’re not anchored securely, they could displace or detach, compromising the protection level they offer.

2. Internal Metatarsal Guards

Contrasting with their external counterparts, Internal Metatarsal Guards are ingrained directly within the shoe structure. They are typically situated between the shoe’s exterior material and its inner lining, ensuring a seamless integration.

Advantages

The most prominent advantage of these internal guards is their secure fit. Since they are integral to the shoe’s design, they eliminate the risk of unexpected shifting or detachment. From an aesthetic perspective, shoes equipped with these guards usually resemble regular safety shoes, ensuring workers don’t compromise on style for safety.

Additionally, many workers have expressed a preference for these guards over external ones due to the comfort and streamlined appearance they offer.

Disadvantages

However, this integrated protection comes with its own set of challenges. Shoes with built-in metatarsal protection are often priced higher than conventional safety shoes. Furthermore, if, for any reason, the guard suffers damage, it could necessitate the replacement of the entire shoe, leading to increased expenses.

Another potential drawback lies in their lack of versatility. Unlike external guards, these can’t be added or removed based on the job’s requirements or the worker’s preference.

When confronted with the decision between external and internal metatarsal guards, various factors come into play. These encompass the specific demands of the job, the regularity of exposure to potential foot hazards, the allocated budget, and individual comfort preferences. Regardless of the choice, it remains paramount to ascertain that the selected guard complies with the prevailing safety standards and aptly addresses the inherent risks of the designated work environment.

Materials Used in Metatarsal Guards

Metatarsal guards are manufactured from various materials, each offering distinct benefits and characteristics that cater to the diverse demands of various occupations and the unique needs of individual users. Here’s a detailed look into some of the primary materials employed in their construction:

1. Steel

Steel is one of the oldest and most widely used materials for protective footwear components, including metatarsal guards. It’s revered for its strength and durability.

- Advantages: Steel offers unparalleled protection against punctures and heavy impacts. Given its robust nature, it can withstand high pressure and extreme conditions, providing consistent protection to the foot.

- Considerations: However, steel is relatively heavy, which can be a drawback for some workers who prioritize lightweight footwear for comfort, especially during prolonged wear. Also, steel can be a conductor of cold and heat, potentially making it less suitable for extreme temperatures.

2. Aluminum

Aluminum offers a middle ground between steel’s heft and the composites’ lightness. It’s a metal lighter than steel but still offers substantial protection.

- Advantages: Aluminum metatarsal guards are generally lighter than their steel counterparts, enhancing comfort without significantly compromising protection. They’re also corrosion-resistant, which can be beneficial in wet or corrosive environments.

- Considerations: While aluminum provides excellent protection, it might not match the absolute strength of steel, especially against extremely heavy impacts.

3. Lightweight Composite Materials

These are modern innovations in the world of protective footwear. Composites can be made from fiberglass, carbon fiber, plastic, or Kevlar.

- Advantages: Composite metatarsal guards stand out due to their lightweight nature, often making them the most comfortable option for prolonged wear. They don’t conduct heat or cold like metals, making them suitable for various temperature conditions. Additionally, being non-metallic, they’re ideal for environments with metal detectors, like certain security checkpoints or airports.

- Considerations: While they offer adequate protection for many jobs, extreme conditions with exceptionally heavy objects might be better suited for metal guards, as composites may not always offer the same level of impact resistance as steel.

In summary, the material selection for a metatarsal guard heavily depends on the specific demands of a job and the individual’s preferences. A construction worker dealing with heavy machinery might opt for steel for its unrivaled protection.

At the same time, an airport employee might lean towards composites for their lightweight nature and non-metallic properties. Whatever the choice, it’s crucial that the selected guard meets the required safety standards for the intended use.

Features to Consider when Selecting Metatarsal Guards

When selecting metatarsal guards, it’s important to consider several features to ensure they provide adequate protection and comfort. Here are some key features to consider:

1. Protection Level

The essence of a metatarsal guard lies in its ability to shield the foot from hazards, emphasizing the need to recognize the particular threats of one’s workplace. In high-risk settings, such as construction sites where heavy machinery operates, the constant looming threat of hefty objects falling mandates a guard constructed of ultra-resilient material with exceptional resistance to impact.

However, in less perilous environments, where the dangers are not as immediate or potent, users might find other attributes more pressing than sheer brute strength. It’s pivotal that regardless of personal priorities, the selected guard adheres strictly to the relevant safety benchmarks set for the work environment.

2. Comfort

Comfort transcends the realm of mere pleasure. It’s a foundational factor ensuring that a worker remains undistracted and can channel their attention wholly to their tasks. An ill-fitting or uncomfortable metatarsal guard can be a source of constant irritation, leading to heightened fatigue, diversion from tasks, and, over extended periods, can even culminate in tangible physical ailments.

The pinnacle of comfort is often found in guards championing ergonomic principles, hugging the foot’s contours gracefully, and minimizing the risk of abrasions or unease. Moreover, a touch of padding can act as a buffer, absorbing shocks and further elevating the comfort quotient.

3. Fit

The synergy between a metatarsal guard and the footwear it adorns is of paramount importance. A misaligned or ill-fitted guard is not just a reservoir of discomfort but a chink in the armor, compromising the user’s safety. An inadequately seated guard can introduce pressure anomalies on the foot, detracting from comfort and safety.

This symbiotic relationship between the guard and footwear is foundational, regardless of whether one opts for an external overlay or an in-built protection mechanism. The union should epitomize seamless integration, acting as a cohesive unit to guarantee protection and ease.

4. Durability

The metatarsal guard’s longevity becomes a vital concern for those treading the rugged terrains of demanding job sites. The durability of a guard isn’t just a testament to its quality but a reflection of its enduring protection.

The choice of materials, married to the finesse of its construction, determines its lifespan. Investing in guards crafted from tenacious materials, bearing the hallmarks of skilled craftsmanship, not only assures sustained protection but, in the grand scheme, is also economically prudent, diminishing the frequency of replacements.

5. Flexibility and Mobility

Protection, though central to a guard’s role, should not encumber mobility. Jobs demanding intricate foot maneuvers or extensive movement warrant a metatarsal guard that blends rigidity with flexibility. Such a balance ensures that while the foot remains shielded from harm, it’s not ensnared in a rigid casing, allowing for fluid movement, whether climbing ladders or navigating complex terrains.

6. Weight

The gravitational pull of a metatarsal guard, or its weight, has a pronounced influence on user comfort and endurance. A guard’s weight can be a double-edged sword. While a heftier guard might be synonymous with enhanced protection, it can also be the harbinger of fatigue during prolonged usage.

Conversely, a feather-light guard, though a delight to don, might skimp on protection. It’s this delicate balancing act, dictated by job specifics, that determines the optimal weight of a guard.

7. Temperature Regulation

The ambient conditions of a workplace play a pivotal role in dictating the metatarsal guard’s design. In torrid conditions, where the sun beats with fury, guards crafted from breathable materials become invaluable, allowing for efficient thermal regulation and warding off excessive perspiration.

On the flip side, in the icy climes of colder regions, the insulating characteristics of a guard rise to prominence, shielding the foot from the biting cold.

Choosing a metatarsal guard is an intricate exercise, requiring a deep understanding of one’s work environment and personal preferences and then juxtaposing them against the myriad features these guards offer.

Standards and Certifications | Metatarsal Guards

Metatarsal guards, akin to other types of personal protective equipment (PPE), must adhere to stringent standards to guarantee they provide the essential level of protection. The American Society for Testing and Materials (ASTM) establishes these standards in the United States.

The ASTM meticulously drafts guidelines and requirements that protective footwear must fulfill, encompassing impact resistance, compression resistance, and durability. Choosing a metatarsal guard is not merely about comfort or design; ensuring that the product has undergone rigorous testing and acquired the necessary certifications is imperative. This ensures that the product will serve its protective purpose effectively and the user’s safety in high-risk environments.

Care and Maintenance Of Metatarsal Guards

The longevity and efficacy of metatarsal guards heavily hinge on their proper care and regular maintenance. Like any equipment that plays a pivotal role in safety, these guards should be subjected to frequent inspections to spot any signs of deterioration or damage.

Over time, even the most robust materials can show signs of wear, which could compromise the protective qualities of the guard. Visible cracks, thinning areas, or broken attachments are red flags that indicate a compromised guard. Any guard showing these signs should be promptly replaced, as a compromised guard can lead to severe foot injuries.

Moreover, hygiene plays a significant role in maintaining metatarsal guards, especially if they’re used in environments exposed to dirt, chemicals, or other contaminants. Regular cleaning, following the manufacturer’s guidelines, is essential. Proper cleaning not only prolongs the lifespan of the guard but also ensures that the user remains protected from potential skin irritations or infections that could arise from accumulated dirt or bacteria.

Regular inspection and cleaning of metatarsal guards are as vital as their initial selection. Proper care ensures they continue to offer optimal protection throughout their usage.

Conclusion

In the vast realm of occupational safety, the nuanced details often make a world of difference. Metatarsal guards, while seemingly simple, embody this principle by offering specialized protection for one of the most vulnerable parts of our body. As we’ve traversed through their intricacies, from types to materials and from selection criteria to care guidelines, it’s evident that these protective shields are more than just accessories; they are indispensable allies in our quest for a hazard-free work environment.

Ensuring you’re equipped with the right guard, aligned with standards, and maintained with care is not just a testament to prioritizing safety but an investment in long-term well-being. As we conclude, let it be a reminder that in the dance of industrial endeavors, every step, when protected, leads to a harmonious and safer tomorrow.