Handling chemicals in industrial, laboratory, and commercial environments carries significant health and safety risks. Chemical exposure can cause severe injuries—ranging from respiratory and skin irritation to long-term damage like cancer, organ failure, or hearing loss. Proper personal protective equipment (PPE) acts as a crucial barrier to mitigate these hazards and ensure worker safety.

However, PPE is most effective when selected and used correctly based on the nature of the chemical hazards. This guide delves into the different types of PPE required for chemical handling, offering insights on how to select, use, and maintain them. With the right PPE in place, workplaces can protect employees, improve morale, and ensure regulatory compliance.

According to the Hierarchy of Controls, PPE should be the final measure used to manage chemical hazards—following elimination, substitution, engineering controls, and administrative measures. While PPE offers essential protection, it relies heavily on correct usage and adherence to safety protocols, making training and supervision vital.

Types of PPE for Chemical Handling

Chemical PPE falls into several categories based on the parts of the body requiring protection. The equipment required depends on the specific nature of the chemical hazards, exposure routes, and environmental risks.

1. Respiratory Protection

When airborne chemicals or fumes present risks to health, respiratory PPE is essential.

- Air-Purifying Respirators (APR): Protect against inhalation of gases, vapors, and particulates. These are suitable when contaminant levels are below certain limits.

- Powered Air-Purifying Respirators (PAPR): Use a fan to supply filtered air, improving comfort and extending wear time.

- Self-Contained Breathing Apparatus (SCBA): Required for high-risk environments with unknown airborne chemical concentrations.

- Disposable Masks and N95 Respirators: Offer minimal protection and are used for non-hazardous or nuisance-level contaminants.

Note: Respirator use requires medical evaluations, annual fit testing, and training to comply with safety regulations.

2. Eye and Face Protection

Chemical splashes and fumes can damage the eyes and face. The appropriate protection depends on the risk level.

- Safety Glasses with Side Shields: Protect against minor splashes and debris.

- Chemical Splash Goggles: Provide a seal around the eyes, preventing exposure to splashes and fumes.

- Face Shields: Worn over goggles when handling highly corrosive chemicals or during tasks with explosion risks (e.g., pyrophorics).

Tip: All eye protection should meet ANSI Z87.1 standards for workplace safety.

3. Hand Protection: Chemical-Resistant Gloves

Hands are often the first point of contact with hazardous chemicals, so selecting the right gloves is crucial.

- Nitrile Gloves: Provide resistance to oils, solvents, and some acids.

- Neoprene Gloves: Offer flexibility and resistance to a wide range of chemicals, including acids and alcohols.

- Butyl Gloves: Ideal for protection against ketones and esters.

- Kevlar Gloves: Used in environments involving heat or cut hazards.

Gloves must be selected based on the chemical compatibility charts provided by manufacturers. Frequent inspections are critical, as damaged gloves offer no protection.

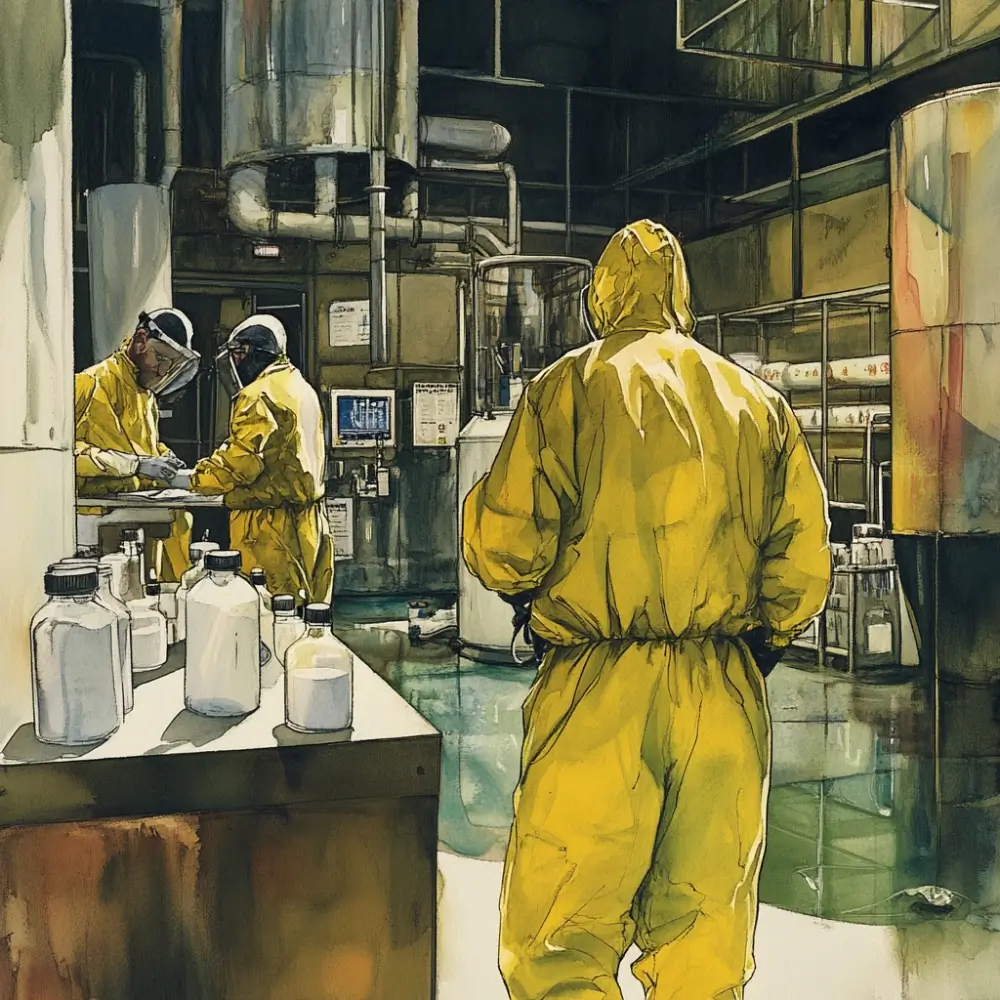

4. Body Protection: Chemical-Resistant Clothing

Body PPE ranges from simple aprons to full-body suits, depending on the hazard level.

- Lab Coats or Coveralls: Used in low-risk environments for general protection.

- Tyvek® Suits: Provide protection against chemical splashes and particles.

- Encapsulated Suits: Required for high-risk environments to prevent exposure to toxic gases and liquids. Often used with SCBAs.

- Flame-Resistant (FR) Clothing: Necessary when handling flammable chemicals, such as pyrophorics.

Clothing should fit properly, cover all exposed skin, and be easy to remove in emergencies.

5. Foot Protection: Chemical-Resistant Boots and Shoe Covers

Chemical-resistant footwear is essential to prevent contact with spills on floors or work surfaces.

- PVC or Rubber Boots: Provide resistance to corrosive chemicals and solvents.

- Steel-Toe Boots: Protect against mechanical hazards and falling objects.

- Disposable Shoe Covers: Useful in laboratories to prevent cross-contamination.

Make sure that footwear fits well and is resistant to the chemicals handled in your environment.

6. Hearing Protection

Chemicals such as solvents and degreasers can damage the auditory nerve, resulting in ototoxicity (hearing loss).

- Earplugs: Suitable for short-term use in noisy environments.

- Earmuffs: Provide better protection and are ideal for continuous noise exposure.

Hearing protection should be used alongside regular hearing tests to monitor potential damage.

Special PPE for Handling Pyrophoric Chemicals

When handling pyrophoric chemicals (substances that ignite spontaneously in air), specialized PPE is mandatory:

- Kevlar® Gloves: Lightweight gloves for thermal protection, covered with disposable neoprene gloves to ensure dexterity.

- Nomex® Lab Coats: Flame-resistant coats, worn with non-synthetic undergarments to reduce static electricity.

- Chemical Splash Goggles with Face Shields: Double protection for eyes and face.

- SCBA Respirators: Necessary in confined spaces or areas with high inhalation risk.

- Closed-Toe Shoes: Essential to prevent foot injuries from spills or splashes.

Key Considerations When Using Chemical PPE

While PPE is essential for safeguarding workers from chemical hazards, its effectiveness depends on proper use, maintenance, and management. Ensuring the right fit, training, and care is crucial for maximizing protection and minimizing risks. Here are the key factors to consider when implementing PPE in your workplace.

- Fit and Comfort Matter: If PPE doesn’t fit well, workers are less likely to wear it properly. Make sure the equipment fits comfortably to ensure it provides the protection needed.

- Proper Training is Crucial: Employees must be trained on how to correctly put on, take off, and maintain their PPE. Without proper training, even the best equipment won’t keep them safe. Chemical signs can reinforce training by providing quick visual cues about the required PPE for specific tasks and reminding workers to follow safety protocols.

- Inspect and Replace Regularly: PPE should be checked thoroughly before each use. Any damaged or worn-out equipment should be replaced immediately to maintain safety standards.

- Store It Right: Proper storage is key. Keep PPE in a clean, dry place to extend its life and ensure it stays in good condition for the next use.

Limitations of PPE

Although PPE is essential for protecting workers from chemical hazards, it has certain limitations that make it less reliable than other control measures. These constraints highlight the importance of using PPE in combination with engineering and administrative controls. Below are the key limitations:

- Dependence on Human Behavior: PPE is only effective if workers wear and use it properly. Inconsistent use or improper handling can significantly reduce its effectiveness.

- Discomfort and Restricted Mobility: PPE can be bulky, restrictive, or uncomfortable, which may lead to reduced productivity or discourage continuous use, especially during long shifts.

- Impaired Vision, Communication, and Dexterity: Face shields, goggles, or thick gloves can limit vision and hand movement, making tasks more challenging and increasing the likelihood of mistakes.

- Maintenance and Wear: PPE must be regularly inspected, cleaned, and replaced. Neglecting maintenance can result in damaged equipment, compromising safety.

- Heat and Fatigue Risks: Full-body suits can cause heat stress and dehydration, especially in hot environments, making it difficult for workers to wear them for extended periods.

- Temporary Protection: PPE does not eliminate the hazard—it only provides a barrier. Exposure risks remain if other controls, such as ventilation, are not in place.

These limitations emphasize the importance of using PPE alongside other control measures in the Hierarchy of Controls to ensure comprehensive workplace safety.

Conclusion

Chemical PPE plays a critical role in safeguarding workers from exposure to hazardous substances. However, it should never be the sole protective measure. By following the Hierarchy of Controls—eliminating or substituting hazards wherever possible and complementing PPE with engineering and administrative controls—organizations can create safer work environments.

With the right PPE, thorough training, and regular supervision, companies can protect their employees, boost morale, reduce turnover, and ensure regulatory compliance. Remember, safety is a shared responsibility, and effective use of PPE ensures that everyone goes home safely at the end of the day.