Ensuring safety while working at heights is paramount in many industries, including construction, maintenance, and telecommunications. A Full Body Safety Harness is a critical component of personal fall protection systems, designed to protect workers from severe injuries or fatalities resulting from falls.

Understanding the various parts of a full-body safety harness is essential for proper usage, maintenance, and overall effectiveness. This guide delves into the essential components of a full-body safety harness, their functions, and best practices for ensuring optimal safety.

Key Components/Parts of a Full Body Safety Harness

A Full Body Safety Harness is an essential piece of personal protective equipment (PPE) designed to safeguard workers from falls in various industries such as construction, maintenance, and telecommunications. Understanding the intricate details of each harness component is crucial for ensuring optimal safety and functionality. This comprehensive guide delves into the key components of a full body safety harness, explaining their roles, features, and best practices for use and maintenance.

1. Shoulder Straps

The shoulder straps are fundamental to the harness’s ability to distribute the forces exerted during a fall. They support the upper body, ensuring that fall forces are spread across the shoulders rather than concentrating on any single point, thereby minimizing the risk of injury.

Features

- Adjustability: Shoulder straps are typically adjustable to accommodate various body sizes and ensure a snug fit. This adjustability allows the harness to remain secure during dynamic movements.

- Padding: Many harnesses incorporate padding on the shoulder straps to enhance comfort, especially during extended wear.

- Alignment: Proper alignment ensures that the harness sits correctly on the user’s back, maintaining balance and reducing fatigue.

Best Practices

- Regular Adjustment: Continuously adjust the shoulder straps throughout the work shift to maintain a secure fit.

- Inspection: Regularly check for signs of wear, fraying, or damage to the shoulder straps to ensure they remain effective.

2. Chest Strap

The chest strap plays a critical role in preventing the harness from riding up over the user’s shoulders during a fall. By anchoring the upper body, it ensures that the harness remains in the optimal position to absorb fall forces.

Placement

- Positioning: The chest strap should be positioned in the mid-chest area, approximately 6 to 8 inches (152mm to 203mm) below the trachea but not below the sternum.

- Height: Proper placement prevents the chest strap from being too high, which could lead to strangulation, or too low, which could allow the harness to shift during a fall.

Adjustment

- Tightness: The chest strap should be tightened enough to keep the shoulder straps taut without restricting the wearer’s range of motion.

- Securing: Ensure that the chest strap is securely fastened and does not have excessive slack.

Best Practices

- Consistent Positioning: Maintain the chest strap’s position throughout use to ensure continuous protection.

- Inspection: Regularly examine the chest strap for signs of wear, damage, or misalignment.

3. Torso Adjustment

The torso adjustment mechanism allows users to customize the fit of the harness, accommodating different body sizes and shapes. This ensures that the harness fits snugly and securely, which is vital for effective fall protection.

Features

- Adjustable Buckles: These facilitate easy tightening or loosening of the harness to achieve the desired fit.

- Multiple Adjustment Points: Located at various straps (e.g., shoulder, chest, leg) to allow comprehensive fit customization.

Importance

A properly adjusted harness ensures that all components function as intended, distributing forces evenly and preventing excessive movement during a fall.

Best Practices

- Personal Fit: Adjust the harness to fit your body before each use, ensuring comfort and security.

- Avoid Over-Tightening: While a snug fit is essential, over-tightening can restrict movement and cause discomfort.

4. Parachute/Tongue Buckle/Quick-Connect Fastener

These buckles secure various straps of the harness, ensuring they remain in place during use. They are critical for the harness’s integrity, allowing for quick donning and doffing while maintaining secure connections.

Types

- Parachute-Style Buckles: Resemble those used in parachutes, allowing for secure and reliable connections.

- Tongue Buckles: Feature a protruding “tongue” that locks into place, providing a secure fastening mechanism.

- Quick-Connect Fasteners: Enable rapid attachment and detachment, enhancing user convenience without compromising safety.

Features

- Durability: Made from high-strength materials to withstand significant forces.

- Ease of Use: Designed for quick and easy operation, even with gloves on.

- Self-Locking Mechanism: Prevents accidental release, ensuring continuous protection.

Best Practices

- Secure Connections: Always ensure that buckles are fully engaged and locked before commencing work.

- Regular Inspection: Check for any signs of wear, damage, or malfunction in the buckles to maintain reliability.

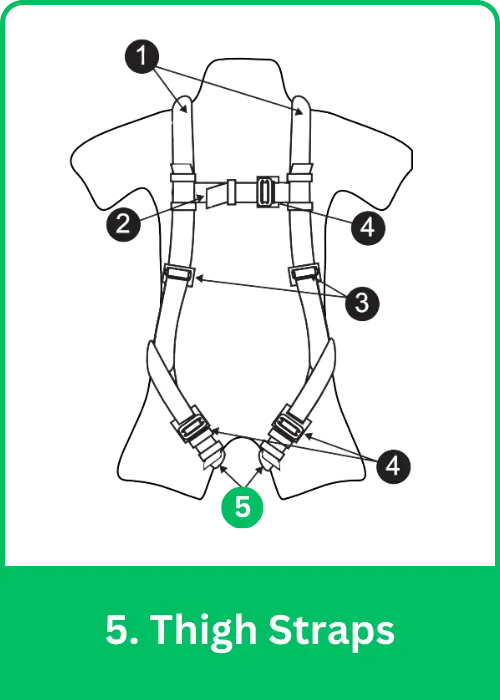

5. Thigh Straps

Thigh straps secure the lower body, preventing the harness from slipping during a fall. They work in conjunction with the shoulder and chest straps to distribute fall forces across the body effectively.

Adjustment

- Snug Fit: Thigh straps should be tight enough to prevent movement but not so tight as to restrict blood circulation.

- Positioning: Positioned between the thighs to provide stable support.

Best Practices

- Comfort and Security: Adjust thigh straps to ensure they are comfortable yet secure, allowing for full range of motion without excessive slack.

- Regular Checks: Inspect thigh straps for signs of wear, fraying, or damage before each use.

6. Dorsal D-Ring

The dorsal D-ring is the primary attachment point for the lanyard in fall arrest systems. It serves as the critical link between the harness and the connecting subsystem, such as a self-retracting lifeline or a lanyard with an energy absorber.

Placement

- Location: Positioned on the back between the shoulder blades, ensuring that fall forces are directed through the strongest parts of the harness.

- Accessibility: Easily reachable for quick attachment and detachment of lanyards.

Usage

- Compatibility: Must be used with compatible connectors to prevent accidental disengagement.

- Single Point of Attachment: Typically, only one D-ring is used for fall arrest to maintain system integrity.

Best Practices

- Secure Attachment: Always attach the lanyard to the D-ring in a way that aligns with the harness’s design specifications.

- Avoid Overloading: Do not exceed the maximum load capacity of the D-ring as specified by the manufacturer.

7. Back Plate

The back plate provides additional support and structure to the harness. It enhances the distribution of fall forces across the back and shoulders, improving overall stability and comfort during use.

Importance

A robust back plate ensures that the harness maintains its shape and effectiveness, especially under dynamic loads experienced during a fall.

Features

- Reinforced Construction: Made from durable materials to withstand significant forces.

- Comfort Padding: Often includes padding to prevent discomfort during prolonged use.

Best Practices

- Proper Fit: Ensure the back plate is correctly positioned and securely attached to prevent shifting during use.

- Inspection: Regularly inspect the back plate for signs of wear, deformation, or damage.

8. Sub-Pelvic Strap

The sub-pelvic strap supports the lower back and pelvis, transferring fall forces away from vital organs. It provides a secure “seat” in a seated position, enhancing user stability and comfort.

Placement

- Location: Positioned around the lower abdomen, ensuring that in a seated position, it comfortably supports the user’s weight.

- Alignment: Proper alignment ensures that fall forces are effectively distributed across the pelvis and lower back.

Best Practices

- Adjust for Comfort: Adjust the sub-pelvic strap to fit snugly without restricting movement or causing discomfort.

- Ensure Stability: Verify that the strap remains in place and does not shift during movement or in the event of a fall.

9. Inspection/ID Label

The inspection/ID label contains vital information such as the model number, serial number, date of purchase, date of first use, and inspection dates. It ensures that the harness is traceable and has undergone necessary inspections.

Importance

Maintains a record of the harness’s usage and inspection history, which is crucial for safety compliance and accountability.

Features

- Durable Printing: Information is typically printed with materials resistant to wear and environmental factors.

- Clear Layout: Organized in a manner that is easy to read and update during inspections.

Best Practices

- Accurate Recording: Ensure all fields are accurately filled out during inspections and maintenance.

- Regular Updates: Update the label promptly after each inspection or maintenance activity.

10. Warning/Instruction Label

Provides essential safety warnings and instructions for proper use of the harness. These labels serve as immediate reminders to users about critical safety information and operational guidelines.

Placement

- Visibility: Strategically placed on the harness for easy visibility, often near the chest or back D-ring.

Content

- Safety Warnings: Highlight potential hazards and incorrect usage practices.

- Operational Instructions: Offer guidance on how to properly don, adjust, and use the harness.

Best Practices

- Read Before Use: Always read and understand the warnings and instructions before using the harness.

- Regular Reference: Refer to the labels periodically to reinforce safety practices.

11. Standards Label

Indicates compliance with relevant safety standards, such as ANSI (American National Standards Institute), OSHA (Occupational Safety and Health Administration), and CSA (Canadian Standards Association). This label assures users that the harness meets industry safety requirements.

Importance

Ensures that the harness has been tested and certified to meet specific safety and performance criteria, providing confidence in its reliability.

Features

- Standard Logos and Numbers: Displayed prominently to signify adherence to particular standards.

- Certification Information: Includes details about the certifying body and the specific standards met.

Best Practices

- Verify Compliance: Check the standards label to ensure the harness complies with the relevant safety regulations for your region and industry.

- Stay Updated: Use harnesses that comply with the latest standards to benefit from advancements in safety technology.

Connectors and Attachment Points

Connectors and attachment points are pivotal components of a Full Body Safety Harness, serving as the critical links between the harness and the surrounding fall protection system. Proper understanding and utilization of these elements are essential for ensuring the safety and effectiveness of the harness during fall arrest scenarios. This comprehensive guide delves into the various aspects of connectors and attachment points, including their types, functions, best practices, and compliance with safety standards.

Connectors and attachment points facilitate the secure connection between the full body harness and other elements of the fall protection system, such as lanyards, lifelines, anchorage points, and rescue equipment. They play a vital role in ensuring that forces generated during a fall are effectively distributed and managed to minimize the risk of injury.

Types of Connectors

1. Self-Locking Snap Hooks

Self-locking snap hooks are designed to securely attach the harness to anchorage points or lanyards. Their self-locking mechanism ensures that the hook remains closed under load, preventing accidental disengagement during a fall.

Features

- Automatic Locking: The gate of the snap hook automatically locks when closed, eliminating the need for manual locking.

- High Strength: Typically rated to withstand at least 5,000 lbs (22 kN) of force, complying with safety standards.

- Ease of Use: Can be quickly connected and disconnected, facilitating swift attachment and removal.

Best Practices

- Ensure Full Closure: Always verify that the snap hook gate is fully closed and locked before use.

- Regular Inspection: Check for signs of wear, deformation, or damage that could compromise the locking mechanism.

- Proper Storage: Store snap hooks in a clean, dry environment to prevent corrosion and maintain functionality.

2. Karabiners

Karabiners are versatile connectors used to link the harness to various components of the fall protection system, including lanyards, lifelines, and anchorage points.

Types

- Locking Karabiners: Feature a manual or automatic locking mechanism to prevent accidental opening.

- Non-Locking Karabiners: Lack a locking mechanism and are typically used where rotational movement is necessary and the risk of accidental opening is minimal.

Features

- Variety of Shapes: Available in different shapes (e.g., oval, D-shaped, pear-shaped) to suit specific connection requirements.

- High Strength: Designed to support substantial loads, meeting or exceeding safety standards.

- Ease of Rotation: Some karabiners are designed to rotate, reducing the risk of gate loading and accidental disengagement.

Best Practices

- Use Locking Karabiners for Fall Arrest: Always use locking karabiners when connecting to critical fall arrest components to enhance safety.

- Avoid Overloading: Ensure that the karabiner is not subjected to forces beyond its rated capacity.

- Proper Orientation: Align the karabiner correctly to minimize stress on the gate and prevent accidental opening.

3. Quick-Connect Fasteners

Quick-connect fasteners allow for rapid attachment and detachment of harness components, facilitating swift donning and doffing of the harness without compromising safety.

Features

- Ease of Use: Designed for one-handed operation, enabling quick and secure connections.

- Self-Locking Mechanism: Ensures that the fastener remains engaged under load, preventing accidental release.

- Durable Construction: Built to withstand repeated use and harsh environmental conditions.

Best Practices

- Ensure Proper Engagement: Always confirm that the quick-connect fastener is fully engaged and locked before use.

- Regular Maintenance: Inspect for signs of wear or damage and replace as necessary to maintain reliability.

- Compatibility Check: Use quick-connect fasteners that are compatible with the specific harness and other system components.

Conclusion

In conclusion, a full body safety harness is an indispensable component of personal fall protection systems, meticulously designed to safeguard workers across various high-risk industries. By comprehensively understanding each key component—from shoulder straps and chest straps to connectors and attachment points—users can ensure the harness functions effectively to distribute fall forces and prevent injuries.

Adhering to best practices for adjustment, regular inspection, and maintenance not only enhances the harness’s reliability but also reinforces overall workplace safety. Moreover, ensuring compatibility with approved connectors and compliance with industry standards like ANSI and OSHA is crucial for maintaining the integrity of the fall protection system.

Ultimately, proper usage, continuous training, and diligent upkeep of the harness are essential steps in minimizing the risks associated with working at heights, thereby fostering a safer and more secure working environment for all.