When working with slings, it is important to ensure your safety and the safety of those around you. You can do several things to ensure your sling use is as safe as possible. This blog post will discuss 13 tips for superior sling safety. Follow these tips to stay safe while using slings!

Material handling safety is one of the most important tasks in any industry. Without it, essential tools, equipment, and materials cannot be moved, sold, manufactured, and utilized. This is why slings are essential tools in almost every industry. Without them, handling materials and transporting them from one place to another would be complex.

But more often than not, loads are too heavy for the slings that support them. Workers get injured or killed because loads fall on them or hit them. The same happens when operators are not trained in the proper use and maintenance of slings. Slings end up being out of the operator’s control or losing their strength because of abuse or wear.

13 Tips for Superior Sling Safety

Here are the top 13 tips to prevent these hazards when using any kind of sling in the workplace:

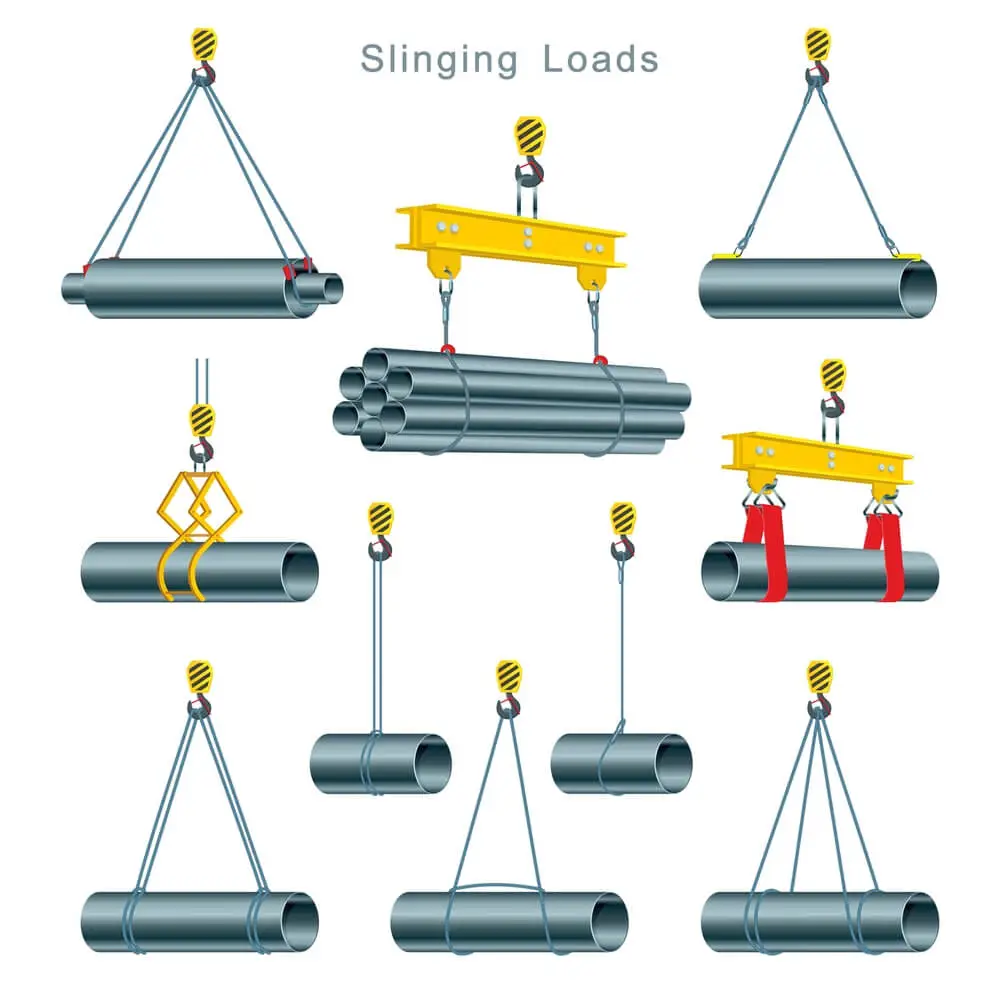

1. Selection Of Slings

Workers must carefully select suitable slings for their intended use as they are an extremely important rigging component. The load’s type, size, and weight must be considered, as well as environmental factors, such as temperature or UV exposure. Not taking into account any of these elements could result in broken or Damaged slings, making them unusable and potentially putting the safety of workers at risk. It is, therefore, incredibly important that the right sling is chosen for each and every task to ensure a successful job.

2. Before Inspecting A Sling, Clean It Thoroughly

Before using any sling, it is essential to thoroughly inspect it for any signs of wear or damage that might render the device unsafe. This is even more important if you use a second-hand or pre-used sling, as dirt and oil can hide the damage that would otherwise be quickly apparent on a newer product.

It is just as important to do the same when returning the sling after use because, unlike much other safety equipment, slings may suffer from micro-fractures that can grow over time and cause serious issues while in operation. If damage of any kind is discovered during inspection, the sling must be replaced immediately. Even if no apparent damage is found, slings should still be cleaned and stored carefully to maintain their effectiveness and lifespan.

3. The Operator Must Inspect A Sling Before And After Using It

Inspecting a sling before and after use is critical for industrial safety and efficiency. Operators should thoroughly examine broken wires, damage to rope strands, and other indications of wear or defects. Failing to inspect the slings before and after use can cause disastrous consequences: these can range from minor financial losses, such as damaged items or disrupted processes, to more severe accidents resulting in injury or even death.

Therefore, heightening the importance of ensuring a sling is always in good condition. The operator must understand their responsibility to properly study each piece of equipment before use and follow each time it has been used.

4. Discard Wire Rope If

Discard wire rope slings when they show the following signs:

- Excessive broken wires

- Severe corrosion

- A one-third reduction in outer wire diameter

- Damage or displacement of end fittings like rings, hooks, collars, and links.

- Distortion, bird caging, kinking.

- Localized wear on the outside

5. Lubricate Every Rope Sling

Properly caring for your rope slings ensures their continued reliability and strength. Lubrication “in the field” is recommended since it can significantly prolong the service life of any sling. The heavier the load, the more adverse environmental conditions, and bend frequency should be considered when deciding how often to lubricate a rope sling. There’s no single answer or perfect time frame, as every rope sling and its environment are different, so exercise caution if you’re unsure and consult an expert. Properly lubricating your rope slings helps maintain their strength and durability – which is crucial for secure lifting jobs.

6. Ensure Loads Are Not Clamped, Lagged, Or Bolted To The Floor

It is important to ensure the safety of both your workplace and the people that work within it; a great way to prevent injuries associated with improper lifting is to never clamp, lag, or bolt loads to the floor. Not only is clamped, lagged, and bolted cargo dangerous, but it can also reduce efficiency as extra time must be taken to rework a load or remove them entirely.

7. Before Lifting Loads, Check The Tension On The Sling

Lifting loads safely is paramount to avoid any accidents, so it’s important to always check the tension on the sling before lifting. You can take a few simple steps to ensure your lift goes smoothly: raise the load a few inches while keeping your eyes trained on its balance; if it seems off-kilter at all, then stop and readjust the sling until balanced correctly. Although these may seem like minor precautions, they can make a difference when operating heavy materials. Take the necessary steps and prioritize safety above anything else!

8. Make Sure The Path Of Travel Is Clear Of Workers

To prevent injuries, it is essential to ensure the path of travel for a load is free from people. Before starting any lift, take a few moments to assess the area and confirm no one is in danger. If possible, have a spotter help guide the load and keep other workers away from the task. Knowing where everyone is can reduce the risk of injury or worse. Paying close attention to the path of travel will ensure that everyone remains safe while lifting heavy items.

9. Employ The Proper Safety Techniques

Taking caution and employing the proper safety techniques to prevent jerking are essential when lifting heavy items. This can be done by slowly taking up the slack in the sling when initially lifting and then slowly accelerating and decelerating the equipment as it starts to move. Being doubly cautious at the beginning of the lift is also necessary to maintain control over the movement of your equipment and protect against any potential shock loading that could occur otherwise.

Using these tips, you’ll be able to move heavier objects confidently, knowing that you have taken every step possible to remain safe during your operation.

10. Operator Must Maintain A Close Watch On The Slings And Equipment

Operating heavy machinery can be intimidating, especially when handling large and potentially dangerous items. Therefore, the operator must closely watch any slings and equipment they are using to mitigate any potential risks. In an accident, the operator must take swift action, immediately shut down all equipment, and report to their supervisor with as much information as possible regarding the incident.

Further steps must be taken to determine the cause of the accident before any operations can begin again. By following these procedures, operators can ensure that accidents can be avoided when dealing with heavy equipment.

11. Only One Person Should Be Assigned To Control A Lift Or Give Signals To The Hoist Or Crane Operator.

The strict protocol must be observed when operating equipment like a lift or crane, as unsafe practices, can potentially result in catastrophic injuries or even fatalities. For this reason, ensuring that only one person controls the lift or gives directions to the hoist operator is crucial. Having multiple people in charge of such duties can easily lead to confusion and errors, so the assignment of a single individual ensures smooth operation; by concentrating both authority and responsibility on one person, safety standards are upheld, and essential operations are not subject to delay or avoidable risk.

12. Never Leave The Load Suspended In The Air

You must never leave the load suspended in the air. This could cause several serious problems, such as crushing or straining other components and weakening the support chain. It’s essential to consistently lower loads gently and safely, ensuring the chain is not under excess pressure.

13. Store The Slings In A Dry, Well-ventilated Building Or Shed

Slings are handy for many jobs; having them in good condition is essential for their proper functioning. Storing them properly is important to ensure that your slings remain in optimal shape and stay ready to use whenever you need them. It’s always best to hang your slings on a wall or rack inside a dry, well-ventilated building or shed. Avoid storing your slings on the ground, as this could create the perfect breeding ground for mold, mildew, and other hazardous materials. Proper storage allows your slings to last longer and work better when needed.

Conclusion

In conclusion, prioritizing safety when working with slings is crucial for reducing accidents and enhancing operational efficiency. The top 13 tips for superior sling safety include careful selection, proper cleaning and inspection, ensuring adequate lubrication, maintaining watchful control during operations, and applying appropriate storage methods. By adhering to these practices, workers can mitigate risks, prolong the lifespan of their equipment, and create a safer and more productive working environment.