Ensuring the safety and well-being of warehouse workers is paramount for any business involved in logistics, distribution, or storage. Warehouses are dynamic environments where employees are exposed to a variety of hazards, from heavy machinery and falling objects to chemical exposures and extreme temperatures. Personal Protective Equipment (PPE) plays a critical role in mitigating these risks, safeguarding workers from potential injuries and accidents.

This comprehensive guide delves into the essential PPE every warehouse should provide, the circumstances under which each type should be used, and additional safety measures to create a secure workplace.

Understanding Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) encompasses a range of gear designed to protect employees from workplace hazards. In a warehouse setting, PPE is crucial due to the inherent risks associated with handling heavy loads, operating machinery, and navigating potentially hazardous environments. Properly selected and maintained PPE can significantly reduce the likelihood of injuries and enhance overall workplace safety.

Why PPE is Crucial in Warehouses

Warehouses are bustling hubs of activity where efficiency and safety must go hand in hand. The importance of PPE in these environments cannot be overstated:

- Reduction of Workplace Injuries: PPE minimizes the risk of accidents, such as cuts, falls, and exposure to harmful substances.

- Compliance with Regulations: Adhering to Occupational Safety and Health Administration (OSHA) standards helps avoid legal repercussions and ensures a safe working environment.

- Enhancement of Worker Confidence: Employees who feel protected are more likely to perform their duties effectively and confidently.

Essential PPE for Warehouse Workers

To maintain a safe warehouse environment, employers must provide appropriate PPE tailored to the specific hazards present. Below are the top essential PPE items every warehouse should have:

1. Safety Helmets (Hard Hats)

Protects the head from falling objects, collisions, and other impacts.

Key Features:

- Impact Resistance: Designed to absorb and distribute the force of impacts.

- Proper Fit: Adjustable straps ensure the helmet stays securely in place.

- Compliance: Must meet safety standards such as ANSI Z89.1 in the United States.

Usage Scenario: Essential when working in areas with overhead storage, stacking, or where heavy machinery operates.

2. Sturdy Footwear (Steel-Toed Boots)

Protects feet from heavy objects, sharp materials, and slippery surfaces.

Key Features:

- Steel or Composite Toe Caps: Provide protection against impact and compression.

- Slip-Resistant Soles: Enhance traction on various floor surfaces.

- Durability: Constructed to withstand harsh warehouse conditions.

Usage Scenario: Mandatory for all warehouse personnel, especially those handling heavy pallets, operating forklifts, or navigating wet areas.

3. High-Visibility Clothing

Ensures workers are easily seen, reducing the risk of accidents in busy environments.

Key Features:

- Fluorescent Colors: Enhance visibility in low-light conditions.

- Reflective Strips: Improve visibility from a distance and in the dark.

- Variety of Garments: Includes jackets, vests, and pants tailored to different roles.

Usage Scenario: Crucial for forklift operators, material handlers, and workers in areas with moving vehicles or machinery.

4. Hand Protection (Gloves)

Shields hands from cuts, abrasions, chemicals, and extreme temperatures.

Key Features:

- Variety of Materials: Includes cut-resistant, chemical-resistant, and heat-resistant options.

- Proper Fit: Ensures dexterity and comfort while maintaining protection.

- Durability: Capable of withstanding repeated use and exposure to hazards.

Usage Scenario: Necessary for tasks involving packaging, handling sharp or heavy materials, and working with hazardous substances.

5. Eye and Face Protection

Guards against flying debris, chemical splashes, and intense light.

Key Features:

- Safety Glasses and Goggles: Provide impact protection and can include UV or chemical filters.

- Full-Face Shields: Offer comprehensive protection for both eyes and face.

- Anti-Fog and Scratch-Resistant Coatings: Enhance visibility and durability.

Usage Scenario: Essential when operating machinery, handling chemicals, or performing tasks that generate dust and debris.

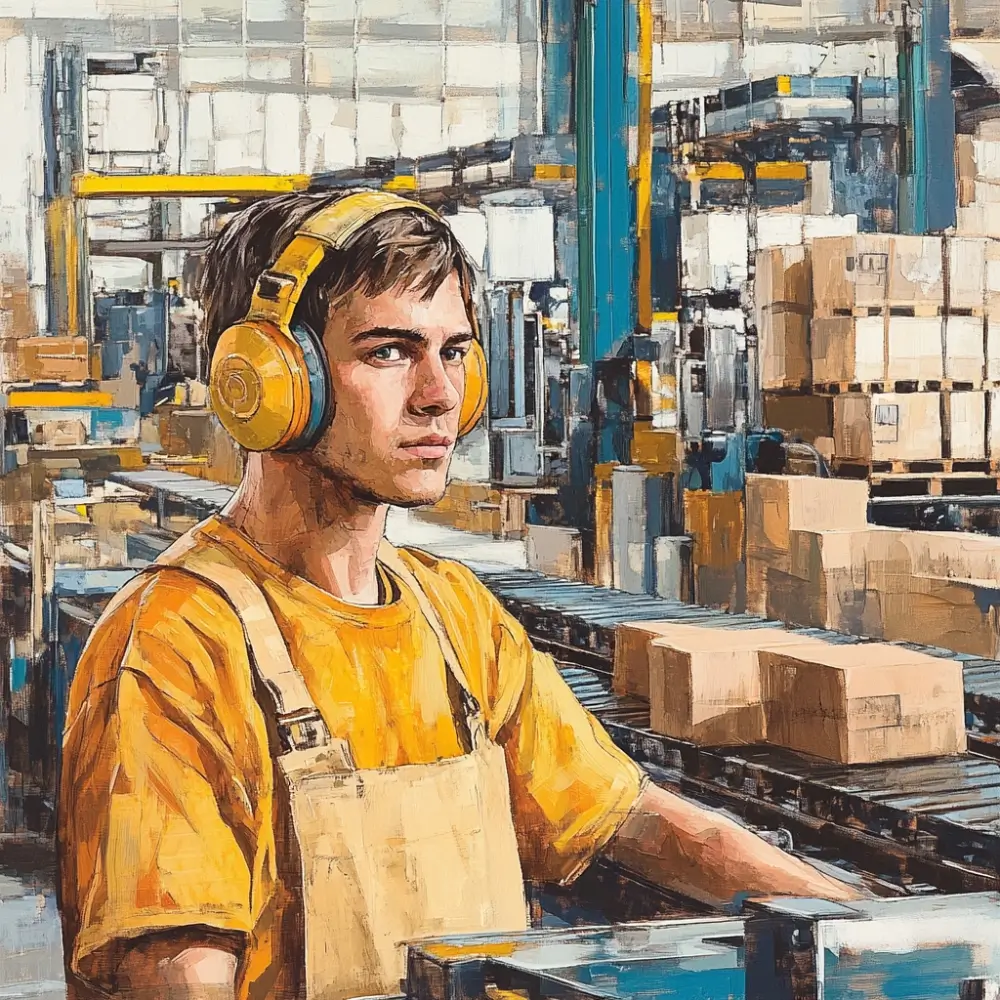

6. Hearing Protection

Prevents hearing loss from prolonged exposure to high noise levels.

Key Features:

- Earplugs and Earmuffs: Available in disposable and reusable options.

- Noise Reduction Rating (NRR): Indicates the level of protection provided.

- Comfortable Design: Ensures compliance and consistent use.

Usage Scenario: Necessary in areas with loud machinery, such as conveyor systems and forklift operations.

7. Respiratory Protection (Masks and Respirators)

Protects workers from inhaling harmful dust, fumes, and airborne particles.

Key Features:

- Variety of Masks: Includes disposable masks, N95 respirators, and higher-grade FFP2 or FFP3 respirators.

- Proper Fit: Ensures an effective seal around the nose and mouth.

- Filter Replacement Indicators: Alerts when filters need to be changed.

Usage Scenario: Required in environments with significant dust generation, chemical handling, or inadequate ventilation.

When to Use PPE in the Warehouse

Personal Protective Equipment (PPE) is a critical component of warehouse safety protocols. Understanding when to use PPE ensures that workers are adequately protected against the myriad of hazards present in a warehouse environment. Here’s an in-depth look at the specific scenarios and conditions that necessitate the use of PPE in warehouses:

1. Operating Heavy Machinery

Operating heavy machinery involves significant risks, including collisions, mechanical failures, and unexpected movements. PPE helps mitigate these risks by providing a barrier between the worker and potential hazards, thereby preventing injuries.

Examples: Forklifts, pallet jacks, conveyor systems, automated storage and retrieval systems (AS/RS).

PPE Required:

- Safety Helmets: Protect against accidental head impacts from machinery or falling objects.

- High-Visibility Clothing: Ensures that operators are easily seen by others, reducing collision risks.

- Steel-Toed Boots: Protect feet from heavy loads that might be dropped or moved unexpectedly.

- Gloves: Enhance grip and protect hands from sharp edges or mechanical parts.

2. Handling Hazardous Materials

Exposure to hazardous materials can lead to severe health issues, including respiratory problems, skin burns, and eye injuries. PPE provides the necessary protection to handle these substances safely, ensuring the health and well-being of workers.

Examples: Chemicals, flammable liquids, corrosive substances, biological hazards.

PPE Required:

- Respirators or Face Masks: Protect against inhaling toxic fumes, dust, or airborne particles.

- Chemical-Resistant Gloves: Shield hands from corrosive or harmful substances.

- Protective Aprons or Overalls: Prevent skin contact with hazardous materials.

- Eye and Face Protection: Safeguard eyes and face from splashes and spills.

3. Working at Heights

Falls from heights are one of the leading causes of workplace injuries in warehouses. Proper PPE ensures that workers are protected from the consequences of such accidents, thereby maintaining a safer work environment.

Examples: Stacking goods on high shelves, using ladders or elevated platforms.

PPE Required:

- Fall Protection Harnesses: Prevent falls from elevated areas by providing a secure attachment to anchor points.

- Non-Slip Footwear: Enhance stability and reduce the risk of slipping when working on elevated surfaces.

- Hard Hats: Protect against falling objects that might dislodge during high-altitude tasks.

4. Exposure to Extreme Temperatures

Extreme temperatures can lead to discomfort, reduced dexterity, and serious health conditions. PPE helps regulate body temperature and protects workers from the adverse effects of environmental extremes, ensuring their safety and comfort.

Examples: Cold storage areas, areas near heating equipment, or open loading docks exposed to weather.

PPE Required:

- Insulated Gloves and Clothing: Protect against cold temperatures, preventing frostbite and hypothermia.

- Heat-Resistant Gear: Shields workers from burns and heat stress in hot environments.

- Thermal Masks or Balaclavas: Provide additional protection for the face and neck in extreme cold.

5. Dealing with Electrical Equipment

Electrical hazards pose serious risks, including fatal shocks and severe burns. Using appropriate PPE when dealing with electrical equipment ensures that workers are protected from these invisible dangers, maintaining their safety during potentially hazardous tasks.

Examples: Maintenance of electrical systems, operating power tools, handling electrical components.

PPE Required:

- Insulated Gloves: Prevent electric shocks and burns when working with live electrical circuits.

- Face Shields: Protect against electrical arcs and sparks.

- Non-Conductive Footwear: Reduce the risk of electrical grounding through the body.

- Protective Clothing: Shields the body from electrical hazards and potential burns.

6. Managing Noise Exposure

Prolonged exposure to high noise levels can lead to permanent hearing loss and other auditory issues. PPE for hearing protection ensures that workers can perform their duties without compromising their long-term hearing health.

Examples: Operating loud machinery, working near compressors, forklifts, and other noisy equipment.

PPE Required:

- Earplugs: Provide a barrier against high noise levels, reducing the risk of hearing damage.

- Earmuffs: Offer continuous protection and are suitable for environments with fluctuating noise levels.

- Noise-Canceling Headsets: Combine hearing protection with communication capabilities in some advanced models.

7. Performing Cleaning and Maintenance Tasks

Cleaning and maintenance tasks often involve exposure to various hazards that can cause injuries or health issues. PPE provides a necessary layer of protection, allowing workers to perform these tasks safely and effectively.

Examples: Cleaning spills, maintaining equipment, handling waste materials.

PPE Required:

- Gloves: Protect hands from chemicals, sharp objects, and biohazards.

- Aprons or Protective Suits: Shield the body from splashes and contaminants.

- Face Masks or Respirators: Prevent inhalation of dust, fumes, or harmful particles during cleaning activities.

8. Emergency Situations

In emergencies, the risk of injury or exposure to hazardous conditions increases dramatically. Having the appropriate PPE readily available ensures that workers can respond effectively while minimizing their risk of harm.

Examples: Fire outbreaks, chemical spills, medical emergencies.

PPE Required:

- Fire-Resistant Clothing: Protects against flames and heat during fire emergencies.

- Respiratory Protection: Essential for dealing with smoke inhalation or toxic fumes.

- Protective Gloves and Boots: Prevent contamination and provide safety during rescue operations.

9. General Warehouse Operations

Even routine tasks in a warehouse carry inherent risks. Consistently using PPE during these activities helps prevent common injuries and maintains a culture of safety within the workplace.

Examples: Loading and unloading shipments, organizing inventory, general material handling.

PPE Required:

- Steel-Toed Boots: Protect feet from heavy or falling objects.

- High-Visibility Vests: Ensure workers are visible to machinery operators and other staff.

- Gloves: Provide hand protection from everyday hazards like sharp edges and rough surfaces.

- Safety Glasses: Shield eyes from dust, debris, and incidental splashes.

10. Confined Spaces

Working in confined spaces presents unique challenges and heightened risks, such as limited ventilation and restricted movement. Proper PPE is crucial to ensure that workers can operate safely in these environments, reducing the likelihood of accidents and health issues.

Examples: Storage tunnels, crawl spaces, maintenance shafts.

PPE Required:

- Respirators or Self-Contained Breathing Apparatus (SCBA): Protect against low oxygen environments and toxic gases.

- Protective Clothing: Guards against physical hazards and contaminants in confined spaces.

- Head Protection: Shields against overhead hazards or accidental impacts in tight areas.

Additional Safety Measures to Minimize Warehouse Dangers

While PPE is essential, it should be part of a broader safety strategy that includes:

1. Comprehensive Training

- Proper Use of PPE: Ensures workers know how to wear and maintain their protective gear.

- Hazard Awareness: Educates employees on potential risks and safe handling practices.

- Emergency Procedures: Prepares workers for incidents like fires, spills, or equipment malfunctions.

2. Organized Workspaces

- Efficient Layout: Reduces clutter and ensures clear pathways for safe movement.

- Proper Storage: Uses shelving and racking systems to keep items secure and out of the way.

- Regular Housekeeping: Maintains cleanliness to prevent slips, trips, and falls.

3. Clear Signage and Labeling

- PPE Requirements: Clearly indicates when and where specific PPE must be worn.

- Hazard Warnings: Uses signs to alert workers to dangers like high noise areas or chemical storage.

- Directional Signs: Guides safe movement through the warehouse.

4. Regular Equipment Maintenance

- Machinery Inspections: Ensures all equipment is functioning correctly and safely.

- Preventive Maintenance: Reduces the risk of unexpected breakdowns or accidents.

- Prompt Repairs: Addresses any identified issues immediately to maintain a safe environment.

Implementing an Effective PPE Program

To maximize the effectiveness of PPE in the warehouse, employers should:

- Conduct Risk Assessments: Identify specific hazards and determine the appropriate PPE needed.

- Develop a PPE Policy: Clearly outlines PPE requirements, usage protocols, and responsibilities.

- Ensure Proper Fit and Comfort: Select PPE that fits well and is comfortable to encourage consistent use.

- Provide Training and Education: Regularly train employees on the importance of PPE and how to use it correctly.

- Monitor and Enforce Compliance: Regularly check that PPE is being worn and maintained properly.

Conclusion

Personal Protective Equipment is a fundamental component of warehouse safety, offering critical protection against a myriad of workplace hazards. By providing the right PPE, conducting thorough training, maintaining an organized workspace, and implementing clear safety protocols, employers can create a secure environment that safeguards their employees’ health and well-being. Investing in comprehensive PPE not only complies with regulatory standards but also fosters a culture of safety and responsibility, ultimately enhancing productivity and employee satisfaction.